How to carefully, firmly and quickly weld a corner at a right angle

To join two pieces of angle at right angles, almost all welders cut the workpieces at 45 degrees. The result is excellent, but only if the trimming is done with a miter saw. When you have to cut with a grinder, distortions are formed. If you don't have a miter saw, it's best to weld the corners at right angles using another method.

Required tools:

- Square;

- marker;

- Bulgarian;

- welding inverter.

The process of cutting and welding 90 degree corners

The corner blanks for welding must first be trimmed. Doing this at 90 degrees with a square is not a problem. You need to mark the edges of each corner flange, and then trim them individually.

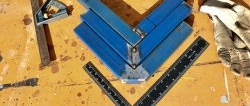

Now the most important thing - you need to cut out a shelf at the edge of one corner to the width of the second. You don’t even need a square here, you can simply attach a second corner and draw a line along it for cutting.

The edge of the cut workpiece inside the corner must be turned flush with the adjacent wall.

Now the parts can be joined and welded. It is better to cook from the inside first with dots, and then with a continuous seam. This way the metal will not move to the side, and the angle will be perfect on all sides.

Watch the video

Similar master classes