How to make an instant heating soldering iron from an old transformer

Amateur soldering irons require a long warm-up before use. To solder one contact, you will have to wait 3-5 minutes until the tip of the tool warms up to the melting temperature of the wire, which is extremely inconvenient. A soldering iron made from an old transformer and parts available on the radio market melts tin 4-5 seconds after switching on.

Materials used

To assemble the soldering iron you will need the following materials:- transformer;

- stranded copper wire;

- copper wire;

- a piece of plywood and a PVC plate;

- switch button;

- PVC pipe with a diameter of 30 mm;

- wire with plug;

- two connectors for connecting wires.

The work takes about an hour.

The process of making a soldering iron with instant heating

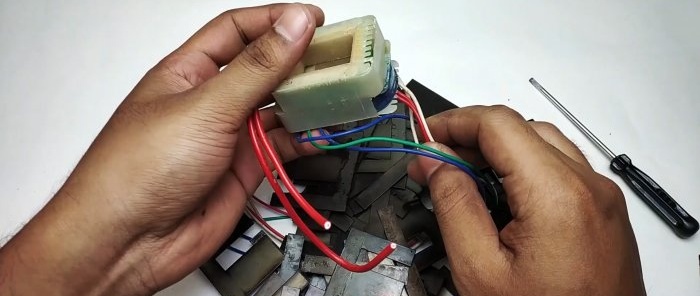

The transformer is pulled out of the housing. The core is removed from the device.

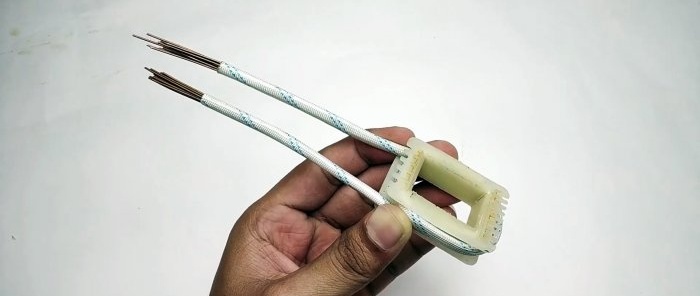

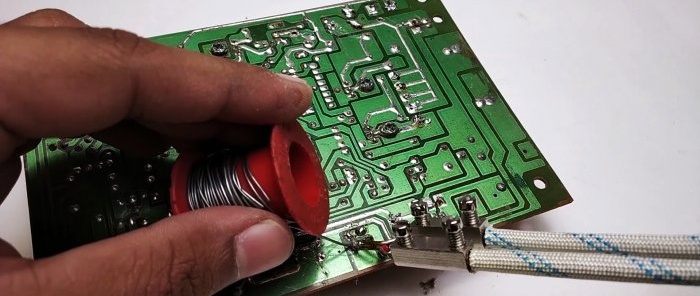

The coils with windings are disassembled, the primary winding is removed. Instead, three turns of a polymer sleeve are wound with a margin.

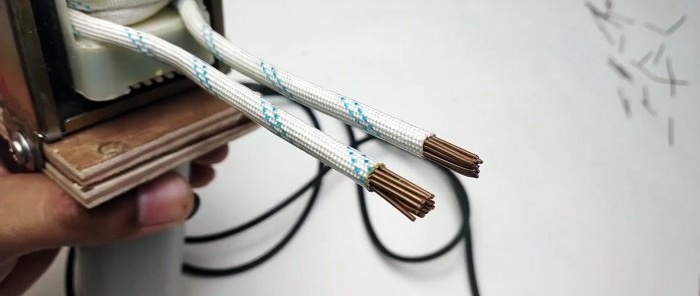

14 strands of copper wire stripped of insulation are cut off, 4-5 cm longer than the polymer sleeve.They are inserted into an insulating sleeve, and it is wound onto a coil in three turns.

The coils are assembled and the magnetic core plates are installed in place.

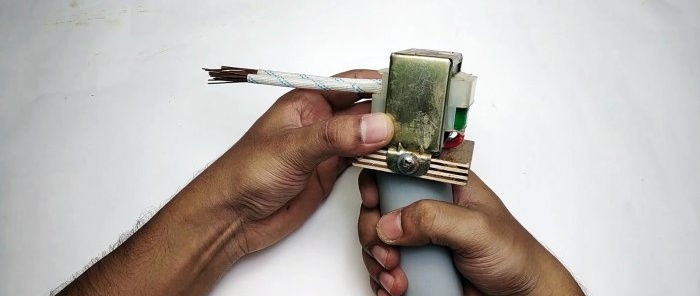

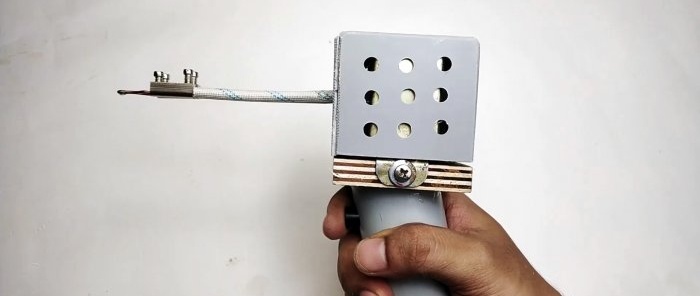

The device is placed in a housing and attached to a piece of plywood. Holes for wires and fasteners are drilled in it.

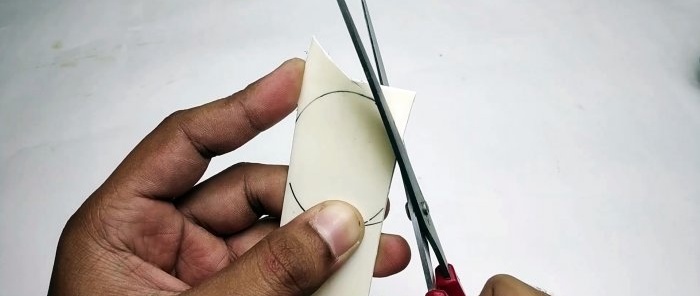

A handle is cut from a PVC pipe.

A spring-loaded switch rated at 3 A is mounted in it.

The toggle switch is connected to the transformer. The handle is glued to the plywood.

The end of the pipe is closed with a plastic or wooden plug into which the cable and plug are threaded. The wires are securely twisted or soldered and insulated.

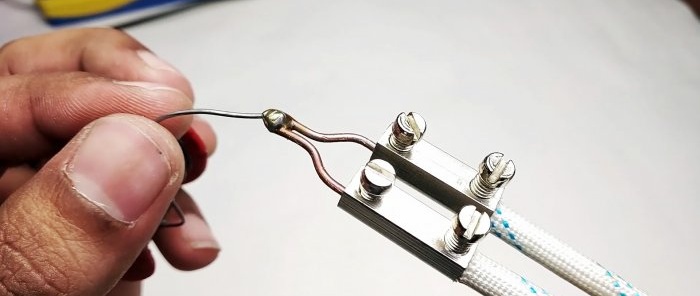

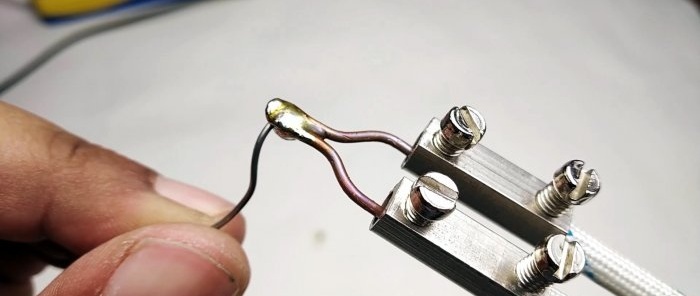

The wires coming out of the sleeve are shortened to approximately 15 mm. Connectors are attached to them.

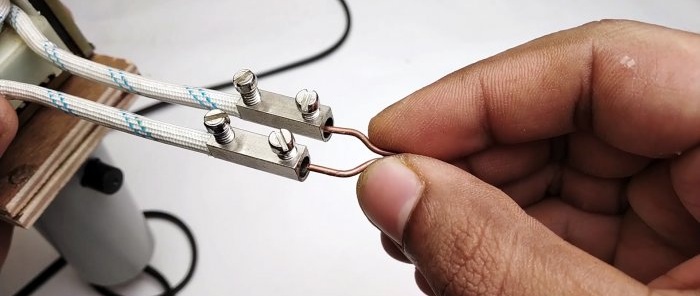

A soldering iron tip is bent from a piece of copper and connected to the outgoing wires using connectors.

Gluing the soldering iron body

After testing, a case is made for the soldering iron that will protect the radio amateur from burns.

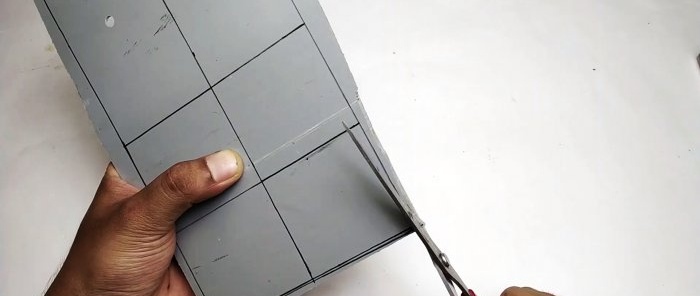

The walls of the housing (five pieces) are cut out of a piece of polyvinyl chloride.

Holes are drilled in four for cooling the transformer, and in the fifth for outgoing wires. The body is assembled and glued.

When working on or with a soldering iron, it is important to follow safety precautions to avoid electric shock or burns. All exposed wires must be insulated.

Watch the video

Similar master classes