An innovative way to connect two wires

Progress does not stand still and a simple heat shrink for wire insulation will no longer surprise anyone. Therefore, now we will talk about a completely new and innovative method of connecting two wires without soldering, twisting in a couple of seconds.

New connectors have appeared on sale that not only insulate, but also solder the wire inside the insulation itself. It is very similar to a simple heat-shrink tube, but unlike it, it not only insulates, but also solders the wires with internal solder!

It looks like science fiction, but let's take a closer look at where to buy it and how to use it.

Will need

- A hairdryer or pocket gas lighter will also work.

- Special heat-shrinkable tubes for splicing wires. You can buy Ali Express.

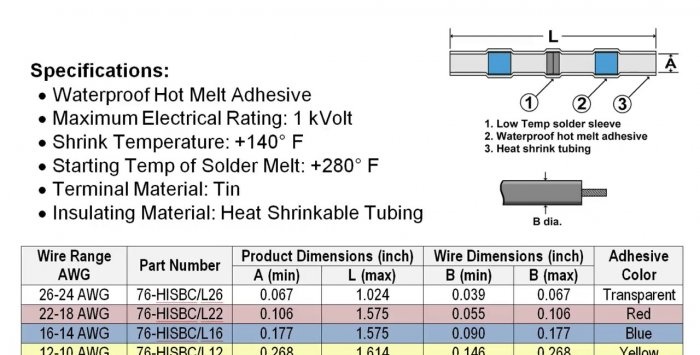

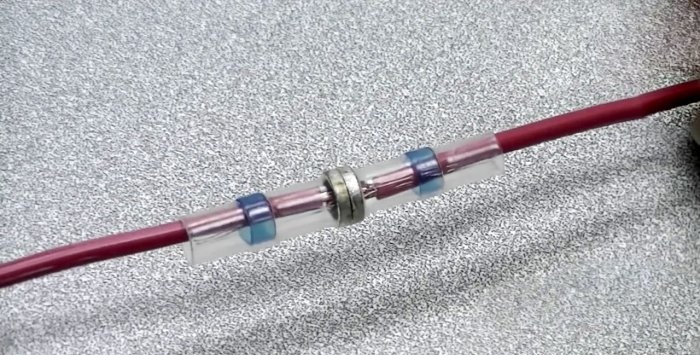

One tube consists of several components:

- - the insulation itself is heat shrink,

- - two crimp rings on the sides – facilitating complete sealing of the entire connection,

- - and a central ring with flux and solder.

Connecting stranded wires

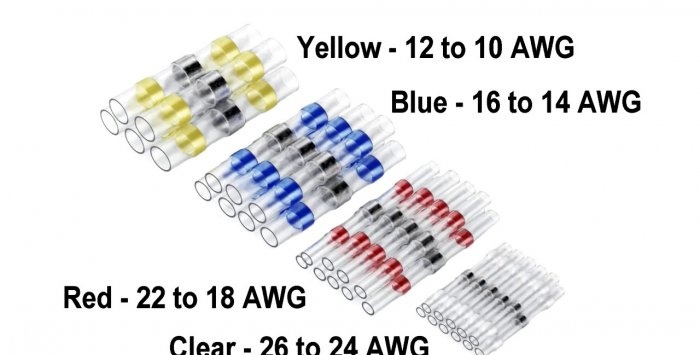

Now practice. First of all, we select the tube of the heat-shrinkable connector to the diameter of the wire being connected (this is why it is better buy a set of these tubes).

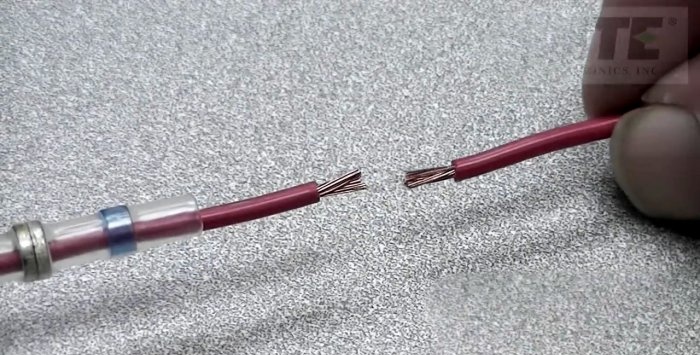

Remove the insulation from both wires, about 1 centimeter on each side. Next, we put a connector on one of the ends.

We connect the fluffy veins by inserting them into each other so that they are intertwined with each other as much as possible.

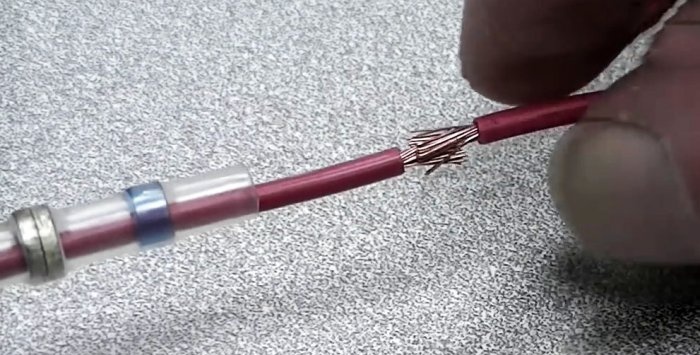

Then you can squeeze this twist a little by hand and put on the connector tube so that the solder ring is exactly in the middle.

Turn on the hairdryer and gently blow on the heat shrink.

To ensure that the tube lies evenly along all the wires, it is advisable to start blowing from the middle.

And as soon as the wires inside are soldered, we begin to blow on the side moisture-resistant rings.

Then let the connection cool for a couple of minutes.

Result:

The result is a moisture-resistant, high-strength connection of two wires. In terms of time, it turns out much faster than with classic twisting.

There is no need to tin or strip the wires. Active flux and solder inside will do the trick.

Since it is quite possible to use a pocket gas lighter instead of a hair dryer, such connectors are a godsend for car enthusiasts.

Watch the video

Similar master classes

Solder sleeves - your salvation when there is no way

How to make tubes for quick soldering of wires from ordinary

The most reliable connection of wires without a soldering iron

The strongest connection of large cross-section wires without thickening

Twisting of wires without soldering that cannot be broken

Methods for connecting wires in a junction box

Particularly interesting

Comments (45)