How to make a resistance welding machine from a car battery

Capacitive batteries for electric bicycles or electric motorcycles are very expensive, so it is cheaper to make them yourself by connecting 18650 batteries together. But to ensure that such an assembly does not fail, jumpers must be welded to the batteries. This is done with a special welding machine, which can be assembled at home.

Materials:

- Copper tube 8-12 mm;

- copper wire 8-12 sq.mm, 1.5 sq.mm;

- heat shrink;

- sheet metal;

- press button;

- starter relay;

- copper wire 4-6 sq. mm;

- wooden stick;

- wide board;

- rail 40x20 mm;

- insulating tape;

- terminal block;

- car battery.

Manufacturing process of a welding machine for connecting batteries

You need to make 2 end terminals for the wire from a copper or brass tube. To do this, its edge needs to be flattened with a hammer, then drilled to the diameter of the starter relay stud. The flattened corners are ground down. After this, the workpiece is cut off with part of the whole tube.

The terminals are installed on the stripped ends of two large-section wires, preferably 12 sq. mm, 30 cm long.

The connection is insulated with heat shrink. You will also need to prepare another similar piece of wire, clean its edges, and place heat shrink in front of the exposed wires.

You need to bend a bracket from any thin sheet metal to install the button. It is made U-shaped with shelves. A hole is drilled in it for the button.

A thin, long, straight wire is connected to the ignition switch terminal on the starter relay. A wire laid through the button is placed on the positive contact. The remaining exposed cores must be insulated with heat shrink.

You need to tape 2 pieces of copper wire to a wooden stick with electrical tape, as in the photo. These will be electrodes for welding. The distance between their contact ends should be 3-4 mm. The terminal block is clamped onto the free edges of the electrodes.

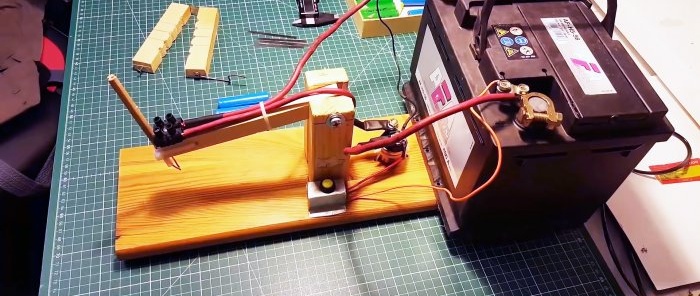

The block is screwed to the edge of the rail section. Now you need to make a swing for welding. To do this, 2 pieces of slats are vertically screwed to the board base with self-tapping screws. Between them, a lever with a block is attached to a bolt axis.

A bracket with a button is installed on the sole. That in turn is connected to the relay. The power contact of the latter must be connected to the terminal block of the electrodes using a wire with an end terminal. A similar cable is laid from the relay to the positive on the car battery. You also need to connect a button to it.

A thick wire is laid from the negative on the car battery to the electrode terminal block. You also need to connect the second wire from the relay to this terminal.

Now you can lower the electrodes onto the batteries in the conductor with the connecting bus pressed. Then, by briefly pressing the button, the plate is welded to the battery. That is, everything is done very quickly and reliably.It is just as difficult to tear off a fixed tire as it is from factory-welded batteries.