How to put leftover foam to good use

Remains of polystyrene foam of various origins should not be thrown away. They will be useful for useful use in the household. But first you need to find out what and how they dissolve.

How to prepare solutions with water-repellent properties and mechanical strength for various surfaces

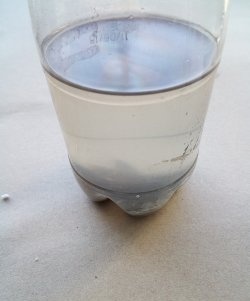

As polystyrene foam solvents, we will test technical acetone, regular acetone (GOST 2768-84), xylene and solvent 646. Pour them in small quantities into separate cups.

Place a piece of foam into each glass. In xylene, a melting reaction is evident. In solvent 646, melting is more active. In regular acetone the process goes even faster. But technical acetone does not dissolve foam at all.

Now let’s dissolve equal-sized blocks of polystyrene foam in the remaining three cups. Melting occurs fastest in acetone, slightly slower in solvent 646 and even quieter in xylene.

A white precipitate formed in acetone. There is practically no sediment in solvent 646, only a little foam is visible on the surface. The same thing is observed in xylene.

Experience shows that a sufficiently viscous solution of polystyrene foam in acetone has good adhesive properties. We also make a mixture of solvent 646 and polystyrene foam. Here the dissolution process is slower and the thickness of the homogeneous mix is somewhat less.

Let's test these 2 solutions by applying them separately to the surface of the foam block. A day after drying, we'll see what comes out of it.

For xylene, take a slightly larger container and melt the foam in it. At the beginning the process goes quickly, and then gradually slows down. As a result, we get an opaque thick liquid.

By adding color to the solution and stirring, we achieve the required color saturation. Apply the resulting composition with a brush to the surface of a technical table outside or in the workshop and leave to dry. We also cover the surface of OSB boards, paving stones and metal with the same solution. In a day we will see the result.

The table dried out after about three hours because it was in the sun. It would take a little longer to dry indoors or under a canopy. Pour water onto the table surface and make sure that it does not penetrate through the applied layer and simply rolls off.

We examine the surface of the foam block, one side of which was coated with a solution of foam in solvent 646, and the other in acetone. The first composition formed a transparent film on the surface of the foam block, while the second - matte.

Their water-repellent properties turned out to be identically high. The mechanical strength when exposed to a nail turned out to be higher in the layer formed by a composition of solvent 646 and foam plastic.

The surfaces of foam blocks, curbstones and OSB, coated with a mix of xylene, polystyrene foam and color, acquired good water-repellent properties. A similar coating on metal turned out to be quite durable and also acquired water-repellent properties.