Foam varnish for painting concrete floors

Due to numerous requests in the comments to my videos, today I will try to make a composition of polystyrene foam and solvents for application to concrete. I would like to see how it will behave, because car owners are interested in cheap varnish to cover the garage against dampness.

I'll start by dissolving the foam in gasoline. I should also check it in acetone and solvent, but I think that acetone dries too quickly. I pour 92 gasoline into a clean, empty metal can. You will need a little more than half the can of gasoline.

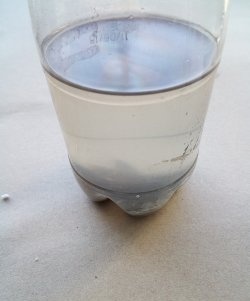

I cut a piece of polystyrene foam approximately 1500 mm long and 40 mm thick into strips and lower them one by one into a jar of gasoline. The width of the strip should be chosen according to the size of the can. My goal is to see how the resulting composition will behave on concrete (I don’t need a lot of varnish). The foam easily fits into the jar, melts and compresses into a fairly dense lump at the bottom.

Note: This will cause the gasoline to bubble and splash out of the can.

The resulting composition has the appearance of a gel and is similar to napalm (when ignited, it immediately flares up, burns for a long time, and the flame is high).It is not possible to regulate the viscosity of the composition by adding gasoline - it reaches a certain thickness and the process stops there. I leave the jar for a while so that the air bubbles come out and all the pieces of foam dissolve.

I take out the gel-like mass from the bottom of the jar and transfer it to another container. I clean the area of the concrete slab with a wire brush and blow off dust with a spray gun. I prepared a brush and a spatula for work, which I lightly greased with oil. This will prevent the varnish from sticking.

It turned out to be more convenient to work with a spatula.

I pour the varnish onto the concrete and use a spatula to apply it to the surface using movements in different directions. After finishing the job, there is practically nothing left on the spatula. When applying the varnish you immediately smell the smell of gasoline. I leave this area for about an hour to dry.

I will conduct the second experiment with xylene (one liter costs 110 rubles). If you cover the entire garage with this composition, then its cost will be 2.5 times more expensive than polystyrene foam varnish dissolved in gasoline. To dissolve in xylene, I chose denser and more expensive fine-grained foam, from which the protection of the computer system unit is made.

When xylene is added to the jar, the foam dissolves almost completely, the viscosity of the composition becomes less, and the thick lump disappears. A composition of this viscosity can be applied in a much thinner layer. It looks like xylene is better for making foam varnish.

Note: I was also advised to use solvent 647, but I didn’t have it on hand.

I'll try using xylene as a wood varnish. I take a walnut branch peeled from the bark and apply a thin layer of the composition with a brush.It turns out very well, but you have to wait for the varnish to dry.

I also apply a layer of composition onto the concrete with a brush. The layer turns out to be very thin and there are no air bubbles in it. I leave it to dry.

My first section did not dry completely within an hour - a film with a very large number of bubbles formed on the surface.

Huge bubbles formed on the sides. To the touch it looks like the well-known packaging film with bubbles. However, as an option, this composition can be used after complete drying.

The area covered with xylene varnish turned out better. The composition is well absorbed into the surface of the concrete and looks like real varnish. The only negative is the high cost of xylene compared to gasoline.

To reduce the cost, you can first dissolve the foam in gasoline, and only then add xylene and achieve the desired viscosity. It will be inexpensive to prepare a composition based on bottled xylene, which is sold in cans and costs less.

Note: the composition dried on wood in 10 minutes and is indistinguishable from real varnish. In the future, for an experiment, I can take a board polished on a machine from a nearby furniture workshop and apply 3-4 layers of xylene varnish to it.

Gasoline and foam

I'll start by dissolving the foam in gasoline. I should also check it in acetone and solvent, but I think that acetone dries too quickly. I pour 92 gasoline into a clean, empty metal can. You will need a little more than half the can of gasoline.

I cut a piece of polystyrene foam approximately 1500 mm long and 40 mm thick into strips and lower them one by one into a jar of gasoline. The width of the strip should be chosen according to the size of the can. My goal is to see how the resulting composition will behave on concrete (I don’t need a lot of varnish). The foam easily fits into the jar, melts and compresses into a fairly dense lump at the bottom.

Note: This will cause the gasoline to bubble and splash out of the can.

The resulting composition has the appearance of a gel and is similar to napalm (when ignited, it immediately flares up, burns for a long time, and the flame is high).It is not possible to regulate the viscosity of the composition by adding gasoline - it reaches a certain thickness and the process stops there. I leave the jar for a while so that the air bubbles come out and all the pieces of foam dissolve.

Covering the concrete floor

I take out the gel-like mass from the bottom of the jar and transfer it to another container. I clean the area of the concrete slab with a wire brush and blow off dust with a spray gun. I prepared a brush and a spatula for work, which I lightly greased with oil. This will prevent the varnish from sticking.

It turned out to be more convenient to work with a spatula.

I pour the varnish onto the concrete and use a spatula to apply it to the surface using movements in different directions. After finishing the job, there is practically nothing left on the spatula. When applying the varnish you immediately smell the smell of gasoline. I leave this area for about an hour to dry.

Dissolving polystyrene foam in xylene

I will conduct the second experiment with xylene (one liter costs 110 rubles). If you cover the entire garage with this composition, then its cost will be 2.5 times more expensive than polystyrene foam varnish dissolved in gasoline. To dissolve in xylene, I chose denser and more expensive fine-grained foam, from which the protection of the computer system unit is made.

When xylene is added to the jar, the foam dissolves almost completely, the viscosity of the composition becomes less, and the thick lump disappears. A composition of this viscosity can be applied in a much thinner layer. It looks like xylene is better for making foam varnish.

Note: I was also advised to use solvent 647, but I didn’t have it on hand.

I'll try using xylene as a wood varnish. I take a walnut branch peeled from the bark and apply a thin layer of the composition with a brush.It turns out very well, but you have to wait for the varnish to dry.

I also apply a layer of composition onto the concrete with a brush. The layer turns out to be very thin and there are no air bubbles in it. I leave it to dry.

My first section did not dry completely within an hour - a film with a very large number of bubbles formed on the surface.

Huge bubbles formed on the sides. To the touch it looks like the well-known packaging film with bubbles. However, as an option, this composition can be used after complete drying.

The area covered with xylene varnish turned out better. The composition is well absorbed into the surface of the concrete and looks like real varnish. The only negative is the high cost of xylene compared to gasoline.

To reduce the cost, you can first dissolve the foam in gasoline, and only then add xylene and achieve the desired viscosity. It will be inexpensive to prepare a composition based on bottled xylene, which is sold in cans and costs less.

Note: the composition dried on wood in 10 minutes and is indistinguishable from real varnish. In the future, for an experiment, I can take a board polished on a machine from a nearby furniture workshop and apply 3-4 layers of xylene varnish to it.

Watch the video

Similar master classes

Particularly interesting

Comments (18)