How to assemble an off-road and powerful scooter

We will use scooter frame, collected some time ago. To do this, remove one of the nodes from it. We bore the central hole of the driven sprocket on a homemade lathe and drill holes for the fasteners.

How to make a motor scooter

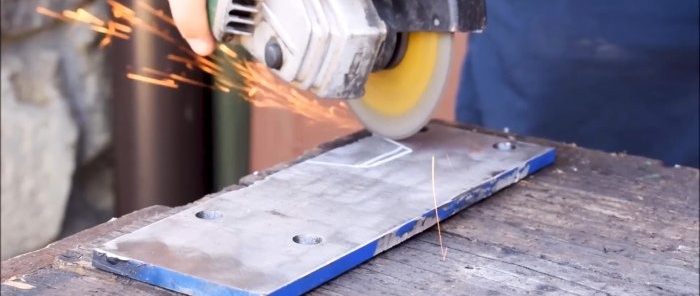

We fit a sheet steel flange in the form of a square with cut corners and a hole in the center to the wheel hub. We put a paper template on it, mark the centers of the holes for fasteners and increase the diameter of the hole in the center by drilling small holes, the centers of which form 2 concentric circles at a short distance from each other. We drill out the jumpers between the holes with a larger drill and remove the weakened metal around the circumference with pliers. We grind off the remaining protrusions with a file.

We place the flange flush on the wheel hub and weld it on the back side. We weld 3 elongated nuts to the second side of the hub behind the ground edge. We will attach the brake disc to them, so when welding the nuts to the hub, we use the brake disc as a template, screwing the nuts to the disc with screws.We fasten the driven sprocket to the wheel hub flange with five round-head bolts and nuts.

We install an inflatable tire with a diameter of 20 cm from the cultivator on the disc and return the brake disc to its place. We thread an axle into the bearings of the disk hub, the ends of which are supported on supports in the form of plates with holes.

In a thick rectangular steel plate, according to the markings on the long side, closer to one end, we make a trapezoidal cutout. In the larger of the intermediate sprockets we bore the central hole.

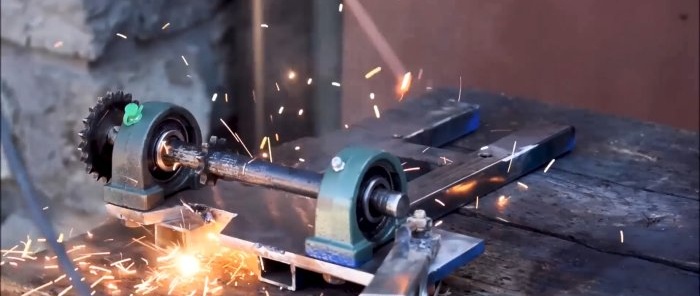

We assemble an assembly for intermediate sprockets from two bearing supports, bushings and an axle. Moreover, we place a large sprocket with 20 teeth outside the bearing support, and a smaller one with 10 teeth – between the supports.

We weld the outer intermediate sprocket to the bushing and secure it with a nut through a wide washer at the end of the axle. We attach the assembly with intermediate sprockets to the thick plate by the legs of the bearing supports so that the cutout is between the supports.

In turn, we attach the plate with an assembly with intermediate sprockets to a welded frame made of profile rectangular pipes. We fasten it to it with bolts and nuts engine. We put a coupling with a drive sprocket on the engine axis and connect it to the outer intermediate sprocket with a chain.

We weld a transverse plate to the body frame and install the engine and a unit with intermediate sprockets. We also connect the smaller intermediate sprocket and the driven sprocket on the wheel with a chain.

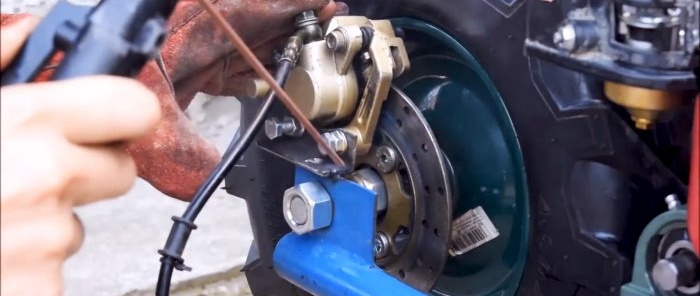

We install the brake mechanism on the brake disc, securing it to the frame by welding.

We attach the wheel to the front fork, secure the brake controls and engine on the steering wheel. The scooter is completely ready for use.