How to make a device for making a strong mesh

6 mm steel wire rod is a fairly durable type of rolled metal, the manual deformation of which is a difficult operation. Moreover, when obtaining a mesh from it, you will need many initial elements with the same type, but numerous bends. The matter will be greatly simplified if you make in advance a device that is simple in design but quite effective.

Will need

Materials:

- 6 mm steel wire rod;

- steel rectangular plate;

- square bar;

- threaded rod with nut;

- 2 bearings on the axle with the heel;

- profile rectangular pipe;

- 4 mounting bolts.

Tools: measuring square, marker, welding machine, grinder, vice, impact wrench.

The process of manufacturing a device for bending wire rod - mesh elements

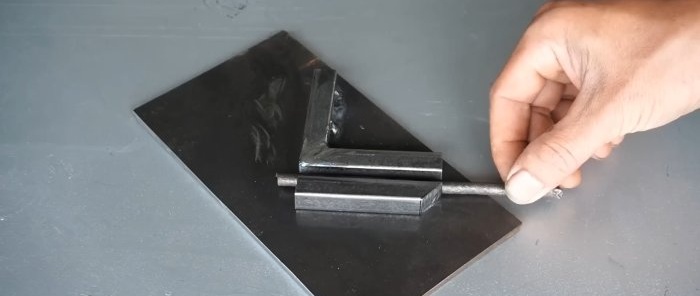

In the center of a rectangular steel plate we place 2 pieces of equal length from a square rod with the ends cut at 45 degrees. After aligning the right angle and fixing it, weld them to the stove and among themselves.

Parallel to one of the sides of the right angle, we weld the same element from a square rod to the plate, after making sure that a 6 mm wire rod fits freely between them.

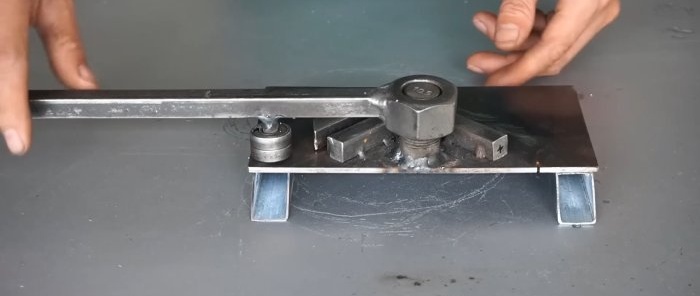

We place a vertically threaded rod in the inner right corner of two square rods and weld it to the plate. Screw the nut onto the rod. We weld a square rod of the estimated length to one of the faces of the nut at 90 degrees.

We install 2 bearings on the axle with the heel on the corner of the plate. Mark the bottom of the square rod on the axis, welded to the nut. We shorten the axis along the marked mark and weld to the bottom of the square bar.

Along the short sides of the slab from below, we place 2 sections of a profile rectangular pipe with beveled ends and weld them to the slab. Through the holes in the profile pipes on four sides, we securely screw our device to the corner of the workbench.

The device works very simply. We move the lever with bearings beyond the line running in the middle between two parallel sections of a square rod. We insert the end of the wire rod blank into the gap between them and pull the lever towards the rod. Then the bearings, rotating, press on the wire rod, and it bends exactly 90 degrees. We bend the next section of the wire rod in the opposite direction, while the first bend is fixed with the second section of the angle made of square rods. We continue the process in this sequence until we reach the second end of the wire rod workpiece.

We bend all the workpieces, which are zigzag elements with bending angles of 90 degrees. We lay them on a flat surface so that they touch each other at the tops of the bends. We secure the contact points by welding and protect them with a grinder to obtain a marketable appearance.

Watch the video

Similar master classes