How to make a chain-link tensioner from bicycle parts

Such a device can be purchased in a store, but you will have to pay a tidy sum. To save money, it can be made from old bicycle parts and scrap metal. This will not require cash costs, scarce materials or professional skills. Any adult can handle this kind of work.

Will need

Materials:

- old bicycle chain;

- steel square rod;

- steel sheet or strip;

- rear bicycle sprocket with ratchet;

- bicycle axle;

- the bolt and nuts are different;

- piece of reinforcement;

- spray paint.

Tools: welding equipment, vice, drill, ruler and marker, pendulum saw and clamp.

The process of making a durable chain-link tensioner from old parts and materials

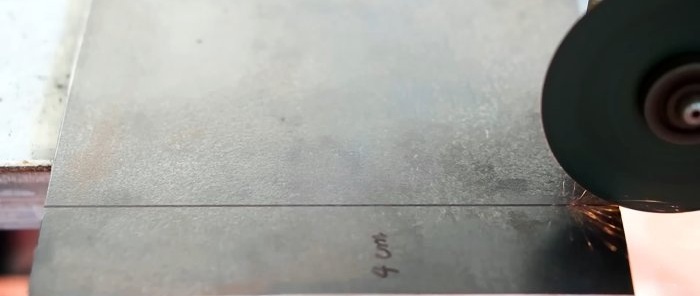

We weld a part of a bicycle chain 20 cm long to a square rod in the longitudinal direction. From the metal strip we cut a strip 4 cm wide and 20 cm long. Place a rod with a welded fragment of the chain on it.

We lay two square rods, 20 cm long, longitudinally on the strip on the sides of the chain.We weld them to the strip so that the rod and chain move freely in both directions.

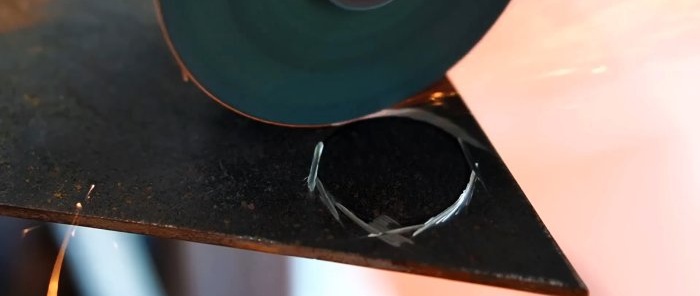

Unscrew the rear sprocket with ratchet from the bicycle wheel. From a metal sheet we cut out two circles with a diameter equal to the internal diameter of the ratchet. We put them on both sides in a ratchet and brew.

We find the center of the welded circles and drill holes in them, where we insert the bicycle axle and weld it in the center of the thread at one end. Cut off the part of the axle outside the thread.

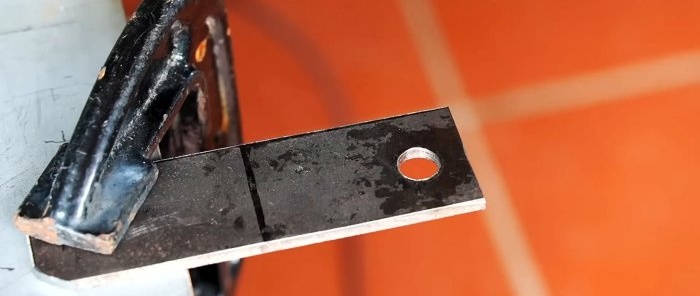

We make 2 plates with holes at the ends in the center and rounded corners. We install a sprocket with a ratchet with a threaded axle at the edge of the chain. We put low nuts with larger threads on both sides of the axle, then we put plates that we tighten with nuts, and in this position we weld them to the rods. After that, unscrew the outer nuts and put them aside.

Long-lasting discs for angle grinders on AliExpress at a discount - http://alii.pub/61bjly

On the protruding parts of the axle we make 2 flats to the plates. In two square rods at one end we make cuts commensurate with the width of the ends of the axle. We cover the flat ends of the axle with the cuts of the rods and cut off the rods at a height slightly greater than the outer radius of the sprocket.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h

We weld a rod of the estimated length to the ends of the rods opposite the slots. We weld a long rod to its center, parallel and opposite to the slotted rods.

We weld a small rod perpendicularly to the end of the bar with the chain welded on the reverse side.On the back side of the strip, to which the guide rods are welded, at a distance of 4 cm from the end, we weld a plate vertically, and to it at the top level, transversely, a rod spanning the entire width of the plate.

On the outside of the rod we weld a nut into which we screw a bolt. We weld a piece of reinforcement across the end of the bolt. Taking certain actions, we paint the tensioner in 2 colors in accordance with its functionality.

After one side of the mesh is welded to the frame, using our device, we stretch the opposite side and also weld it to the frame. As a result, the mesh smoothes out and becomes elastic.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Watch the video

Similar master classes