How to drill through any high-speed steel with a tile drill

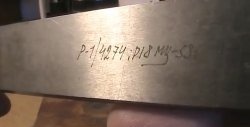

How to drill high-speed steel grade P6M5 or HSS according to the European designation? For example, we made a knife from a blade from a mechanical saw, and we need to drill holes in it with a diameter of 5-6 mm for pins to install and secure the handle pads.

The same operation may be needed to drill a hacksaw blade for metal from 1Х6ВФ steel, from which you can make some useful products. A piece of blade from a mechanical saw made of 9HF steel is suitable not only for making knives, but, for example, also non-standard keychains.

All of the considered and other grades of high-speed steels are drilled using spear-shaped (feather) drills for tiles, having different designs. For example, shanks are made round or hexagonal, which is not of fundamental importance for the main work - drilling.

They are freely sold in almost all construction stores or outlets selling all kinds of tools.What is very important, drills of this type and purpose are attractive because they are inexpensive.

Also, for drilling high-speed steels, you will need cutters of various shapes and designs. With their help, the accuracy, cleanliness, shape and required diameter of the drilled hole are ensured.

We have to drill the following samples:

Let's start with a hacksaw blade for metal. As a tool, we will choose a used tile drill bit, which has already been sharpened more than once on a diamond wheel. That is, for a long time nothing remained of the factory sharpening, which would have undoubtedly given the best result.

We insert our tool into the chuck of an electric drill and start drilling without the use of lubrication or cooling. We select low speed as the operating mode. We notice that the process is slow, but with some patience, after some time a conical depression appears on the blade, a kind of countersink caused by the shape of our drill.

We drill until a tubercle appears on the other side.

After this, we turn the canvas over and continue the process, focusing on the tubercle.

Alternately drilling from one side to the other, we achieve an increase in the diameter of the hole until we get the desired size.

The next sample is a blade from a frame saw. We select the drilling location at the base of the teeth, where the material has the greatest hardness.

The process also does not proceed very quickly, but steadily. This can be seen by the gradually increasing volume of chips around the drill.

We notice that the work goes faster if you slightly rock the tool from side to side. This helps remove chips from the cutting area.

We continue drilling on one side until the tip of the tool passes the entire thickness of the metal and forms a small tubercle on the other side of our sample.

Since the thickness of the metal is greater than that of a metal blade, we will have to replace the drill halfway through the process or resharpen the one we are using. After this, we turn the sample over and continue drilling.

After just a few turns of the drill, a through hole is formed. Continuing the process, we achieve the required diameter for the mating part.

Make the hole using a suitable cutter.

In our case, it is most convenient to use a conical-shaped tool. It is easier and faster to achieve the required hole size and give it a cylindrical shape.

After all, after using a feather drill with its large taper, the hole turns out to be different in diameter: closer to the surface of the sample it is larger, and in the center it is smaller.

Let's start drilling the blade from a mechanical saw.

To do this, we also choose a zone closer to the teeth, since in this place the metal is harder due to special hardening.

The process seems to be faster compared to the previous two samples. This can be seen from the intensity of chip formation and the production of a through hole without drilling from the reverse side.

One of the cutters will help bring the hole to the desired diameter and give it a cylindrical shape, as in previous cases.

In practice, we have been convinced that any grade of high-speed steel can be drilled with ordinary Chinese feather drills for tiles, the main advantages of which are accessibility and a cheap price.Also in this case, standard cutters are useful, with the help of which the diameter of the holes is specified and they are given a cylindrical shape.

Using linseed oil for drilling (it is used when working with stainless steel and contains oleic acid), it will be possible to increase productivity, sharpen the tool less often and improve the cleanliness of processing.

Practice shows that the process of drilling high-speed steels will become more productive if you first use drills of a smaller diameter, and then a larger one.

Some craftsmen use screws or screws made in Germany and used for concrete work as tools for drilling high-speed steels. Their distinctive feature is that on the head there is the letter “H” (Hardened - hardened).

The same operation may be needed to drill a hacksaw blade for metal from 1Х6ВФ steel, from which you can make some useful products. A piece of blade from a mechanical saw made of 9HF steel is suitable not only for making knives, but, for example, also non-standard keychains.

Necessary tools and samples

All of the considered and other grades of high-speed steels are drilled using spear-shaped (feather) drills for tiles, having different designs. For example, shanks are made round or hexagonal, which is not of fundamental importance for the main work - drilling.

They are freely sold in almost all construction stores or outlets selling all kinds of tools.What is very important, drills of this type and purpose are attractive because they are inexpensive.

Also, for drilling high-speed steels, you will need cutters of various shapes and designs. With their help, the accuracy, cleanliness, shape and required diameter of the drilled hole are ensured.

We have to drill the following samples:

- a piece from a frame saw made of 9HF steel.

- blade from a hacksaw for metal made of steel grade 1Х6ВФ.

- Mechanical saw blade made of HSS steel.

The process of drilling high-speed steel samples

Let's start with a hacksaw blade for metal. As a tool, we will choose a used tile drill bit, which has already been sharpened more than once on a diamond wheel. That is, for a long time nothing remained of the factory sharpening, which would have undoubtedly given the best result.

We insert our tool into the chuck of an electric drill and start drilling without the use of lubrication or cooling. We select low speed as the operating mode. We notice that the process is slow, but with some patience, after some time a conical depression appears on the blade, a kind of countersink caused by the shape of our drill.

We drill until a tubercle appears on the other side.

After this, we turn the canvas over and continue the process, focusing on the tubercle.

Alternately drilling from one side to the other, we achieve an increase in the diameter of the hole until we get the desired size.

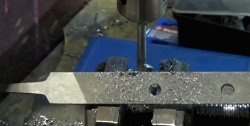

The next sample is a blade from a frame saw. We select the drilling location at the base of the teeth, where the material has the greatest hardness.

The process also does not proceed very quickly, but steadily. This can be seen by the gradually increasing volume of chips around the drill.

We notice that the work goes faster if you slightly rock the tool from side to side. This helps remove chips from the cutting area.

We continue drilling on one side until the tip of the tool passes the entire thickness of the metal and forms a small tubercle on the other side of our sample.

Since the thickness of the metal is greater than that of a metal blade, we will have to replace the drill halfway through the process or resharpen the one we are using. After this, we turn the sample over and continue drilling.

After just a few turns of the drill, a through hole is formed. Continuing the process, we achieve the required diameter for the mating part.

Make the hole using a suitable cutter.

In our case, it is most convenient to use a conical-shaped tool. It is easier and faster to achieve the required hole size and give it a cylindrical shape.

After all, after using a feather drill with its large taper, the hole turns out to be different in diameter: closer to the surface of the sample it is larger, and in the center it is smaller.

Let's start drilling the blade from a mechanical saw.

To do this, we also choose a zone closer to the teeth, since in this place the metal is harder due to special hardening.

The process seems to be faster compared to the previous two samples. This can be seen from the intensity of chip formation and the production of a through hole without drilling from the reverse side.

One of the cutters will help bring the hole to the desired diameter and give it a cylindrical shape, as in previous cases.

In practice, we have been convinced that any grade of high-speed steel can be drilled with ordinary Chinese feather drills for tiles, the main advantages of which are accessibility and a cheap price.Also in this case, standard cutters are useful, with the help of which the diameter of the holes is specified and they are given a cylindrical shape.

Final Tips and Notes

Using linseed oil for drilling (it is used when working with stainless steel and contains oleic acid), it will be possible to increase productivity, sharpen the tool less often and improve the cleanliness of processing.

Practice shows that the process of drilling high-speed steels will become more productive if you first use drills of a smaller diameter, and then a larger one.

Some craftsmen use screws or screws made in Germany and used for concrete work as tools for drilling high-speed steels. Their distinctive feature is that on the head there is the letter “H” (Hardened - hardened).

Watch the video

Similar master classes

Particularly interesting

Comments (23)