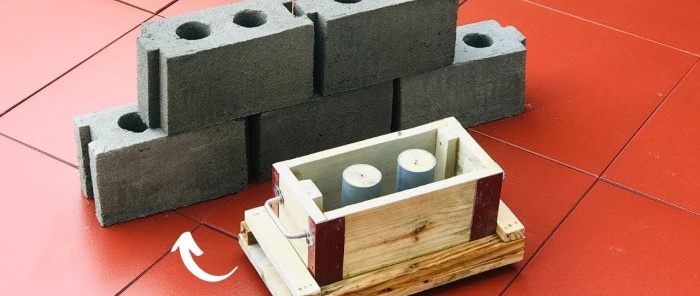

How to Make a Wooden Lock Block Mold

Purchasing ready-made sand-cement blocks with delivery is associated with high costs. But they can be cast on site using wooden molds that any adult can make.

Will need

Materials:

- wooden blocks of different sizes;

- pieces of wooden board of different lengths;

- metal corners;

- nails and screws;

- plastic pipe;

- door handles;

- cement, sand and water.

Tools: tape measure and marker, wood saw, hammer, drill, container for mixing mortar and construction trowel.

The process of making a wooden mold for casting hollow sand-cement blocks

We will need wooden blocks 3 and 5 cm wide, pieces of boards 16×15 and 28×15 cm. The dimensions of the blanks depend on the size of the blocks that we are going to cast and may be different.

From these blanks and 4 metal corners 15 cm long, we assemble a quadrangular box using nails. In two corners we nail bars 3 cm wide and 15 cm long. To the opposite side in the center we vertically attach a beam 5 cm wide and 15 cm long with nails.

We place the box on the board and transfer the inner contour of the box onto it. We transfer the box onto 2 adjacent boards. On the outside of the box, along the long sides, we place bars on boards, protruding from the sides beyond the dimensions of the box. We lay 2 shorter bars across the ends of the bars. We nail the bars to the boards at the corners.

We turn the assembly over and nail two bars across to the base of two boards. We transfer the inner contour of the box to the boards and remove it.

We find a point that is 4 cm from the nearest transverse contour line and 5 cm from the side line. We install a plastic pipe with a diameter of 6 cm symmetrically to this point and transfer its outer contour to the boards. We repeat this procedure on the other side.

Use a core drill to drill out the contours of the plastic pipes in the boards. We insert plastic pipes into the resulting holes until they stop at the tabletop and, at the level of the top of the boards, draw transverse rings on the pipes with a marker.

Using a grinder, we make a system of slots from the ends of the pipes to the applied transverse rings. Use a grinder to make small indentations in a circle around the rings.

We heat the end of the pipes with the slots with a gas burner, insert them from the front side into the holes in the boards, bend the resulting tabs onto the boards in the form of daisies and nail them to the boards. We drive mugs cut from boards flush into the pipes from above.

We put the box in place. We nail door handles to its lid and sides.

Wet the box, bottom and lid with water. Mix a solution of cement, sand and water in a container. We fill the mold with it, periodically compacting the solution in the mold by shaking.

After filling the mold with the solution, compact and smooth the solution over the top of the mold.We keep the solution in the mold for a short time, then turn it 180 degrees, take out the base of the mold with two plastic pipes and set it aside.

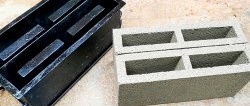

Place the lid on top of the box and, holding it with your fingers, carefully remove the box. A block with voids in the form of two through holes and external locks remains on the site.

Watch the video

Similar master classes

Particularly interesting