Master class on bending plywood to any radius

When making stands, shelves or radius fronts from plywood, it may be necessary to bend it. It is difficult to steam the workpiece and twist it; moreover, with increasing humidity, products made in this way tend to flatten over time. By performing bending using this method, you can completely eliminate this possibility.

What you will need:

- Miter circular saw;

- wood glue;

- tie belt.

The process of bending plywood

The essence of the method is to make many non-through cuts on the workpiece to be bent with a small step in order to weaken it at the bend. As a result, the part will easily bend along the sawn area, and if you fill the cuts with glue, then after drying it will remain that way. The essence of the process is not complicated, the main thing is to correctly calculate the step of making cuts and their number in order to obtain exactly the bend radius that is needed. This can be done on various equipment.

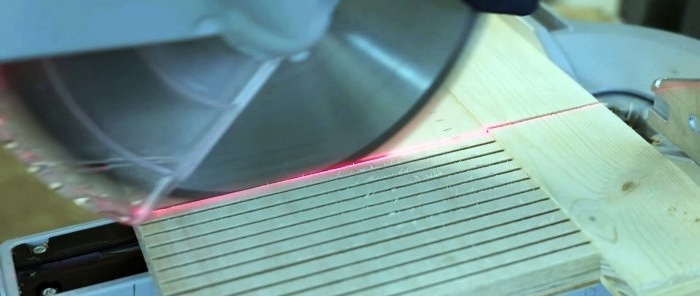

If you have a miter saw with a broach, you can cut the workpiece with it, of course, if the width of the part matches the capabilities of the tool.When working with plywood, the sawing depth is adjusted so as to cut all layers of veneer except the last one.

Afterwards, glue is poured into the cuts, and the plywood blank is bent.

It needs to be fixed in this position. This is done with a tightening belt. Exposed adhesive should be removed immediately.

Similarly, you can make cuts on a saw table. The tabletop circular saw must be equipped with a cross-cutting carriage.

The method will also work when using a hand-held circular saw using a level guide. The main thing is to ensure that the cuts are parallel and that the space between them is the same.

Multilayer plywood bends best. Dry solid wood boards are prone to cracking, even if weakened by cuts, so this method may not work on them.

It is better to determine the number of cuts for a certain bending radius experimentally using unnecessary trimmings of the same material. It all depends on the thickness of the plywood and the width of the cuts left by the disk. The rule here is simple - the steeper the arc, the more often cuts are needed, and the longer it is, the more of them are required.

And finally, you can evaluate the strength of such a bend depending on what kind of glue the workpiece is fastened with - carpentry or polyurethane. Strength tests have shown that in this case the carpentry one holds better.

Watch the video

Similar master classes