Wago terminal blocks: purpose, explanation of markings and subtleties of application

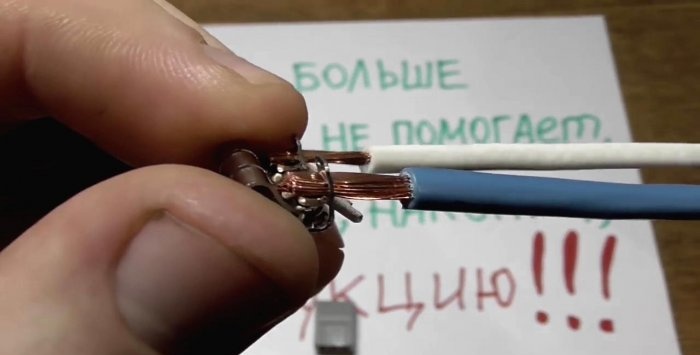

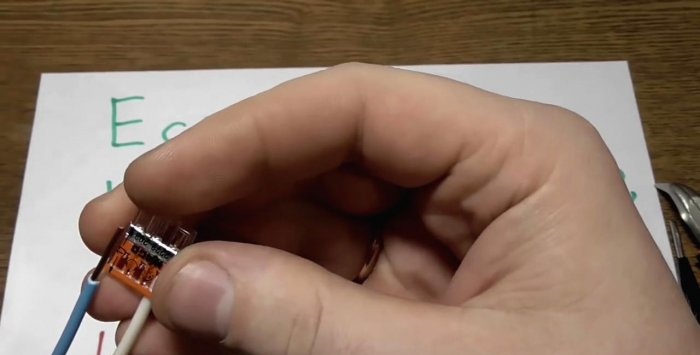

Twisting and soldering are a very reliable way to connect wires, but such methods are not always convenient. When performing electrical installations, many people prefer to use Wago clamps. They quickly connect wires and allow them to be disassembled multiple times and then reconnected. Terminal blocks of this type are produced in several series.

These are reusable clamps with a lever. They come in 2, 3 and 5 nests. On their body there is a technological hole for control devices (current detector, multimeter). The series is intended for rigid and flexible wires with a core cross-section from 0.08 to 2.5 sq. mm. The clamp is also suitable for very flexible wires with fine-wire cores up to 4 sq. mm, having flexibility class 5 and 6.

Wago 222 are intended for use with copper wires only. There are inscriptions on the terminal block housing with information about the load currents. On the sides there are data according to the standards of Japan and the USA, where the mains voltage is 110V. For European countries and Russia, information about currents is indicated below.It is stamped on the body of the clamps that they can be used on wires with a cross-section of up to 2.5 square meters. mm with load current up to 24A. When using very flexible wires 4 sq. mm current 32A allowed.

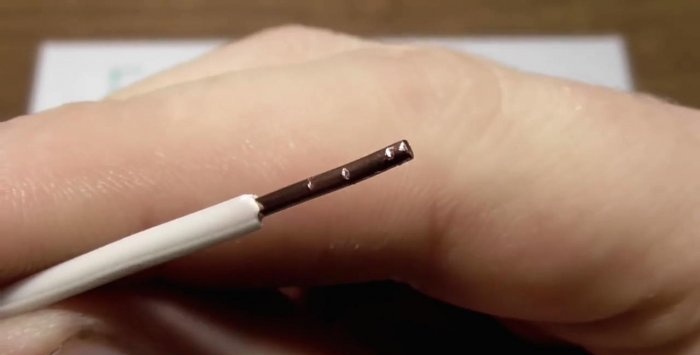

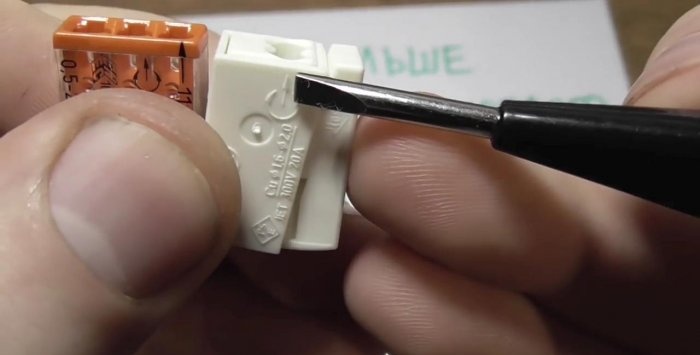

An important condition for electrical installation is the introduction of a straight conductor into the clamp body without bends or traces of oxide. It must be stripped of insulation to a fixed length of 10 mm, which is indicated on the back of the terminal block.

If there is no stripper, stripping can be done manually and its length can be checked by placing the end of the wire against a special mark on the back of the clamp, which is found on any series. If you strip too short, the insulation will get into the clamp and there will be no contact.

If you overdo it with the length, the clean core will protrude from the terminal block, which can result in electric shock.

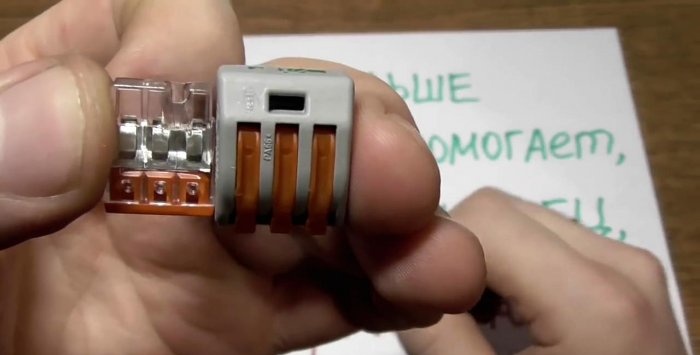

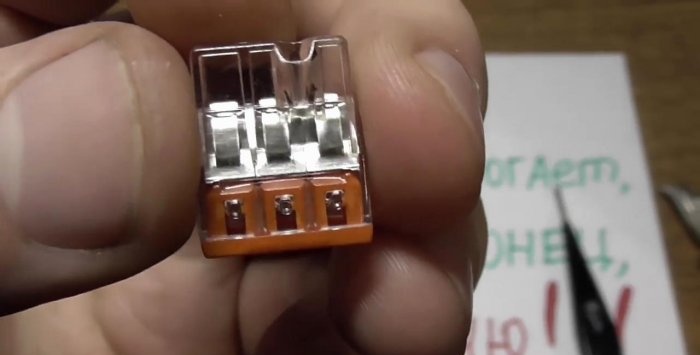

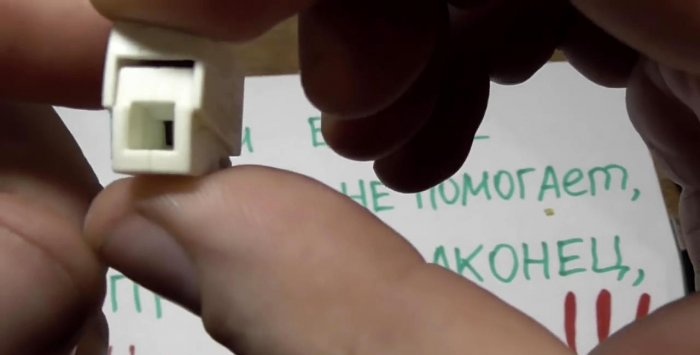

A distinctive feature of Wago series 221 lever terminal blocks is the presence of two technological sockets for measuring voltage parameters. Such blocks have a transparent body, which allows you to visually control the process of clamping the cores.

Wago 221 is significantly more compact than the 222 series. They allow installation of wires with a cross-section from 0.2 to 4 sq. mm. Permissible load current up to 32A, regardless of the type of wires. The series is intended only for copper conductors.

This series is also equipped with a transparent housing for visual inspection of the clamp. It has a socket for indicator devices. It can be used to connect only monolithic wires with a cross-section from 0.5 to 2.5 square meters. mm, since it is not equipped with a lever, so the core must be pushed in to fix it. The series is primarily intended for copper conductors.For connecting aluminum wires, it is available in a version with a special paste inside the terminal block, which prevents oxidation of the metal. Clamps 2273 are designed for connecting wires in a junction box. Another option for using them is to build up a broken aluminum wire in a socket box. The permissible load current for such clamps with a wire cross-section of up to 2.5 kV. mm is up to 24A. When using modified clamps with paste for aluminum conductors, the load current is up to 16A.

The 2273 series also has marks on the back of the housing to monitor wire stripping length. The main condition for using the option with paste for connecting aluminum wires is the need to clean the surface of the conductors from oxide to shiny metal.

The principle of clamping in this series requires that, after fastening, the wires are laid in the mounting box with a bend at some distance from the terminal block. If mechanical stress is created, the conductors may pop out under load.

The series differs from the previous ones in that it has a conditional input with 2 wires and one output. It is used to connect to a monolithic wire with a cross-section of 1-2.5 square meters. mm. At the output it is possible to fix rigid and flexible wires with a cross-section of 0.5-2.5 square meters. mm.

Series 224 is designed specifically for connecting luminaires. The clamps are fixed on the main wire with a solid core, and allow connection with flexible wires that go directly to the lighting equipment. The series includes an option with paste for aluminum conductors.The presence of two inputs on the clamp allows the installation of lighting equipment under the loop, which may be required when wiring spotlights. There is also the option of using series 224 clamps to temporarily connect an extension cord to a wire without installing an outlet, which is important when carrying out construction and repair work in rooms with unfinished electrical installations.

Compliance with all the subtleties of electrical installation and choosing the correct Wago clamp guarantees a reliable connection without the risk of overheating the terminal block or loss of contact. Wago clamps are not limited to the 222 series, which is often used in absolutely all cases, including in conjunction with aluminum conductors. When performing electrical installations, you must initially calculate what connections will be made and select the appropriate type of clamps for them. This will guarantee safety and reliability.

Series 222 – only copper!

These are reusable clamps with a lever. They come in 2, 3 and 5 nests. On their body there is a technological hole for control devices (current detector, multimeter). The series is intended for rigid and flexible wires with a core cross-section from 0.08 to 2.5 sq. mm. The clamp is also suitable for very flexible wires with fine-wire cores up to 4 sq. mm, having flexibility class 5 and 6.

Wago 222 are intended for use with copper wires only. There are inscriptions on the terminal block housing with information about the load currents. On the sides there are data according to the standards of Japan and the USA, where the mains voltage is 110V. For European countries and Russia, information about currents is indicated below.It is stamped on the body of the clamps that they can be used on wires with a cross-section of up to 2.5 square meters. mm with load current up to 24A. When using very flexible wires 4 sq. mm current 32A allowed.

An important condition for electrical installation is the introduction of a straight conductor into the clamp body without bends or traces of oxide. It must be stripped of insulation to a fixed length of 10 mm, which is indicated on the back of the terminal block.

If there is no stripper, stripping can be done manually and its length can be checked by placing the end of the wire against a special mark on the back of the clamp, which is found on any series. If you strip too short, the insulation will get into the clamp and there will be no contact.

If you overdo it with the length, the clean core will protrude from the terminal block, which can result in electric shock.

Series 221 – for copper!

A distinctive feature of Wago series 221 lever terminal blocks is the presence of two technological sockets for measuring voltage parameters. Such blocks have a transparent body, which allows you to visually control the process of clamping the cores.

Wago 221 is significantly more compact than the 222 series. They allow installation of wires with a cross-section from 0.2 to 4 sq. mm. Permissible load current up to 32A, regardless of the type of wires. The series is intended only for copper conductors.

Series 2273 – copper and aluminum!

This series is also equipped with a transparent housing for visual inspection of the clamp. It has a socket for indicator devices. It can be used to connect only monolithic wires with a cross-section from 0.5 to 2.5 square meters. mm, since it is not equipped with a lever, so the core must be pushed in to fix it. The series is primarily intended for copper conductors.For connecting aluminum wires, it is available in a version with a special paste inside the terminal block, which prevents oxidation of the metal. Clamps 2273 are designed for connecting wires in a junction box. Another option for using them is to build up a broken aluminum wire in a socket box. The permissible load current for such clamps with a wire cross-section of up to 2.5 kV. mm is up to 24A. When using modified clamps with paste for aluminum conductors, the load current is up to 16A.

The 2273 series also has marks on the back of the housing to monitor wire stripping length. The main condition for using the option with paste for connecting aluminum wires is the need to clean the surface of the conductors from oxide to shiny metal.

The principle of clamping in this series requires that, after fastening, the wires are laid in the mounting box with a bend at some distance from the terminal block. If mechanical stress is created, the conductors may pop out under load.

Series 224 – for copper and aluminum!

The series differs from the previous ones in that it has a conditional input with 2 wires and one output. It is used to connect to a monolithic wire with a cross-section of 1-2.5 square meters. mm. At the output it is possible to fix rigid and flexible wires with a cross-section of 0.5-2.5 square meters. mm.

Series 224 is designed specifically for connecting luminaires. The clamps are fixed on the main wire with a solid core, and allow connection with flexible wires that go directly to the lighting equipment. The series includes an option with paste for aluminum conductors.The presence of two inputs on the clamp allows the installation of lighting equipment under the loop, which may be required when wiring spotlights. There is also the option of using series 224 clamps to temporarily connect an extension cord to a wire without installing an outlet, which is important when carrying out construction and repair work in rooms with unfinished electrical installations.

Compliance with all the subtleties of electrical installation and choosing the correct Wago clamp guarantees a reliable connection without the risk of overheating the terminal block or loss of contact. Wago clamps are not limited to the 222 series, which is often used in absolutely all cases, including in conjunction with aluminum conductors. When performing electrical installations, you must initially calculate what connections will be made and select the appropriate type of clamps for them. This will guarantee safety and reliability.

Watch the video

Similar master classes

The three most reliable ways to connect wires in

Methods for connecting wires in a junction box

The strongest connection of large cross-section wires without thickening

Soldering strands of aluminum and copper wire

About storing computer cables

Twisting of wires without soldering that cannot be broken

Particularly interesting

Comments (3)