How to solder aluminum

Aluminum is a very attractive metal for constructing your own homemade structures: it is lightweight, perfectly processed, drilled, sawed, does not rust, etc. But here’s the problem: welding two pieces of aluminum without special argon welding is almost impossible. And the equipment for such welding costs more than one thousand rubles. But it turns out there is a way out! This is soldering! But not simple, but using special powder-rod solders.

Will need

So, what do we need to solder two parts to one another:

- Rod (electrode) for soldering aluminum.

- Gas-burner.

- Metal brush.

- Clamp.

- Vise.

Rod solder for soldering aluminum can be found in technical stores for welding work. But due to its narrow focus, its application is quite difficult to find, and the price is quite expensive.

The most affordable way is to buy it at Ali Express - link to solder.

It's inexpensive there, take a pack right away - it will come in handy over time.

This is what it looks like without packaging. An ordinary piece of wire in appearance, but not quite: inside this rod there is a special powder.

The melting point is indicated in Fahrenheit; if we convert it to convenient units, it will be 370-400 degrees Celsius.

We solder aluminum with our own hands

Let's proceed directly to soldering. First you need to prepare the surface of the metals. We take a coarse metal brush and clean the area of future soldering.

To be more precise, it is necessary not only to clean the surface from various dirt and oxides, but also to create a coarse roughness for better adhesion of the solder to the surface.

Using this method, you need to clean both parts at the site of the future connection.

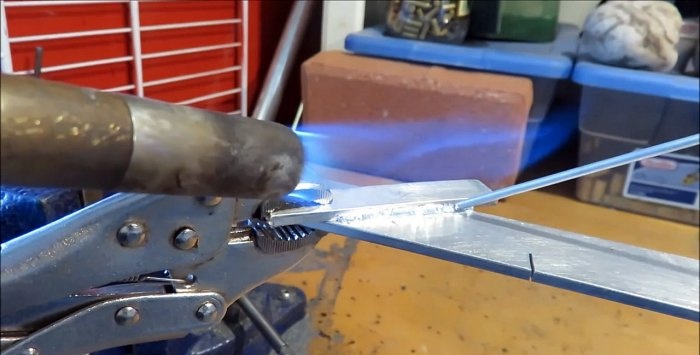

Now we fix the parts with a clamp and clamp everything in a vice for stability and reliability.

We take a gas burner. Moreover, the thicker the metal, the more powerful the burner must be, capable of heating the parts to soldering temperature.

We heat the connection.

After some time, use the soldering rod to touch the heated parts for a second.

If there is no melting, continue heating.

Let's try again. And as you can see, the solder began to melt.

Without removing the burner, spread the solder along the connecting seam. It spreads great.

After the solder is evenly distributed, wait a couple of seconds for the solder to flow into all accessible places.

Next, turn off the burner and wait for it to cool completely.

Connection strength

Of course, this is not arc welding, but it holds up very well, no worse.

I managed to break the connection only by breaking it! But here, it seems to me, the welding would have fallen off. So friends, the soldering method is reliable.

Conclusion

In conclusion, I would like to say that this method can not only solder aluminum parts, but also repair products made of aluminum, duralumin, and silumin. By the way, in auto repair shops they often seal aluminum radiators, but they charge the same fee for welding work using argon.

Watch the video

Watch the video where you will see with your own eyes the entire process of soldering aluminum parts.

Similar master classes

Particularly interesting

Comments (5)