How to properly shorten a bolt

Good advice and a useful trick on how to shorten a bolt, stud or screw. The fact is that if you cut the threads in the usual way, you will no longer be able to screw the nut back onto the threads. All this happens due to the fact that the threaded turns are wrinkled.

There is a simple way out to avoid this.

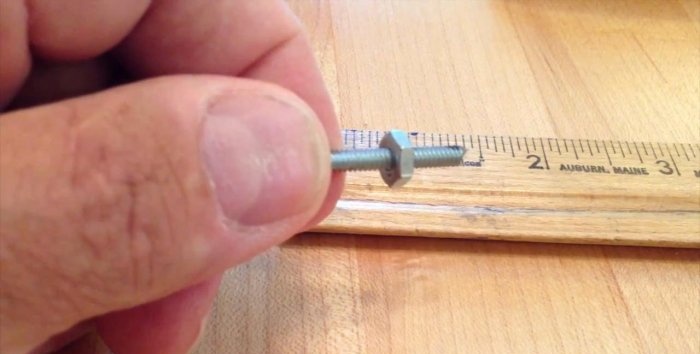

So I'll take a screw as an example. Use a marker to mark the place for the cut. We measure with a ruler.

Screw 1-2 nuts onto the bolt beyond the mark. In general, the nuts should be on the side that you will need later.

Now let's cut it off. Depending on the thickness, this can be done in several ways:

It's not important for you to choose.

I bit it off with wire cutters because the screw is thin. Of course, this is the crudest method, but it is fast.

Now hold the nut with pliers and use a screwdriver to remove the screw.This is the trick: after unscrewing, the nut will straighten all the threads at the tip of the cut.

It is better to screw on two nuts; they will better correct the entire thread.

Now, you can easily screw nuts onto this cut screw.

This is how you can easily preserve all the working properties of a bolt, stud or screw after cutting.

There is a simple way out to avoid this.

Will need

- A bolt, stud or screw that needs to be cut and shortened.

- Nut, 1-2 pcs., with the same thread.

Cutting a bolt, stud or screw correctly

So I'll take a screw as an example. Use a marker to mark the place for the cut. We measure with a ruler.

Screw 1-2 nuts onto the bolt beyond the mark. In general, the nuts should be on the side that you will need later.

Now let's cut it off. Depending on the thickness, this can be done in several ways:

- Bite off with nippers.

- Cut with a grinder.

- Saw off with a hacksaw.

- Clamp it into a screwdriver and rotate the bolt and cut it off with a hacksaw.

- Or another way.

It's not important for you to choose.

I bit it off with wire cutters because the screw is thin. Of course, this is the crudest method, but it is fast.

Now hold the nut with pliers and use a screwdriver to remove the screw.This is the trick: after unscrewing, the nut will straighten all the threads at the tip of the cut.

It is better to screw on two nuts; they will better correct the entire thread.

Now, you can easily screw nuts onto this cut screw.

This is how you can easily preserve all the working properties of a bolt, stud or screw after cutting.

Watch the video

Similar master classes

Particularly interesting

Comments (10)