How to harden a screwdriver bit

Our market is simply flooded with low-quality Chinese tools. And it’s not even a matter of the manufacturer, but rather of resellers who massively bring in cheap Chinese screwdrivers, passing them off as a brand. There are also excellent, high quality Chinese instruments, but they are quite difficult to find.

We won’t talk much about what and how, but we will try to improve the quality of a screwdriver or screwdriver with replaceable bits.

I will harden the bat. Hardening has the goal of increasing the strength of steel, changing the properties of the metal, making it harder, but more brittle.

The hardening process is extremely simple and does not require any special knowledge or special work techniques from you. But you will have to be especially careful when working with hot metal and a gas burner.

So, what do you need for hardening?

Let's start hardening the metal.To hold the bat over the burner, you need to make a holding device. I'll make this out of regular steel wire, wrapping a few turns around the bat.

In principle, you can simply hold the thick end of the bit with pliers so that only the part of the bit that interacts with the screws and screws is hardened.

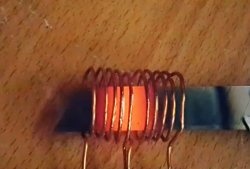

We light the gas burner. We bring the bat and start heating the metal.

Heat until bright pinkish. It is not recommended to heat it until white, although you are unlikely to be able to do this on such a burner.

As soon as everything is warmed up, quickly lower it into the oil for 5-6 seconds. Then we take it out.

You can use another process: 4 seconds in oil, and then sharply in cold water, they say the effect is better, but again, I have not tried it.

That's all. The process is complete. All that remains is to wipe off the oil from the bat and start using it.

It looked darker.

I would like to add that not all bits can be hardened. I don’t know what is mixed into them, but there are specimens that are not only not affected by hardening, but even destroy them, and they become like plasticine after heat treatment.

I would also like to add that this method is in no way similar to factory hardening, so there is no need to expect the same hardness of the metal. Since even the metal is not the same as the factory one. But there is still an effect of increasing hardness, and therefore operating time.

We won’t talk much about what and how, but we will try to improve the quality of a screwdriver or screwdriver with replaceable bits.

I will harden the bat. Hardening has the goal of increasing the strength of steel, changing the properties of the metal, making it harder, but more brittle.

How to harden metal with your own hands

The hardening process is extremely simple and does not require any special knowledge or special work techniques from you. But you will have to be especially careful when working with hot metal and a gas burner.

So, what do you need for hardening?

- - The bits themselves come first.

- - Heater. Ideally use induction heater, but if you don’t have one, you can use a gas burner like I did.

- - Machine oil. Any kind will do, it’s even better to use used one, as it’s thinner.

Let's start hardening the metal.To hold the bat over the burner, you need to make a holding device. I'll make this out of regular steel wire, wrapping a few turns around the bat.

In principle, you can simply hold the thick end of the bit with pliers so that only the part of the bit that interacts with the screws and screws is hardened.

We light the gas burner. We bring the bat and start heating the metal.

Heat until bright pinkish. It is not recommended to heat it until white, although you are unlikely to be able to do this on such a burner.

As soon as everything is warmed up, quickly lower it into the oil for 5-6 seconds. Then we take it out.

You can use another process: 4 seconds in oil, and then sharply in cold water, they say the effect is better, but again, I have not tried it.

That's all. The process is complete. All that remains is to wipe off the oil from the bat and start using it.

It looked darker.

I would like to add that not all bits can be hardened. I don’t know what is mixed into them, but there are specimens that are not only not affected by hardening, but even destroy them, and they become like plasticine after heat treatment.

I would also like to add that this method is in no way similar to factory hardening, so there is no need to expect the same hardness of the metal. Since even the metal is not the same as the factory one. But there is still an effect of increasing hardness, and therefore operating time.

Watch the video of bit hardening

Similar master classes

Particularly interesting

Comments (17)