How to make a household press from any hand jack

You can expand the functionality of any manual jack – mechanical or hydraulic – by giving it the capabilities of a mini-press. This does not require special knowledge, professional skills or high costs.

Will need

Materials:

- profile square pipe 4×4×40 cm;

- equal angle corner 5×5 cm;

- thick steel plate 12x14 cm;

- metal strip;

- finger with a round head;

- steel ring;

- manual jack;

- extension spring;

- spray paint, etc.

High-quality and durable drills on AliExpress at a discount - http://alii.pub/5zwmxz

Tools: tape measure, square and marker, grinder, 2 thin tin plates, welding, drilling machine, pliers.

The process of making a mini-press from any hand jack and scrap metal

We cut blanks 7 cm long from an equal angle corner of 5x5 cm. We lay them in pairs around a profile square pipe, putting 2 thin metal plates between them, and weld them.

We drill a through hole in the center of one slider.On one side of the profile square pipe, at a distance of 3.5 cm from one edge, we drill 4 holes in increments of 5 cm.

To a thick base plate 12x14 cm in the center of the 12 cm side we weld a vertically profiled square pipe with the holes facing up.

We cut 2 blanks 10 cm long from the steel strip. We weld the sliders from the equal angle angle to one side, aligning their lower parts. Moreover, the holes in the slider must be parallel to the welded side of the strip workpiece.

We strengthen the sliders and strip blanks with two gussets, welding them from the side edges of the sliders to the corners of the strip blanks.

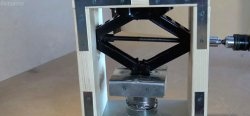

We first put a slider without holes on a stand made of a profile square pipe with holes, then a slider with holes so that the strip blanks are directed towards each other.

We fix the slider with the holes on the stand by passing a finger with a round head through the matching holes.

We slightly unscrew the thrust head screw from the jack and put a steel ring on it. Using a pump, we rest the jack head against the lower strip blank. We turn the assembly over and weld the ring to the strip blank.

We return the unit to its original position and, releasing the pressure in the jack, lower the slider without holes to the lower position. We weld plates for the spring to the base of the stand made of a profile square pipe and the slider.

Having put the jack in place in the lower position, we attach a tension spring between the plates to return the lower stop to its original position after releasing the pressure in the jack.

We paint the resulting mini-press in 2 colors according to the functionality. With its help, you can install bearings in seats, deform workpieces, etc.

Welding electrodes for general purposes on AliExpress at a discount - http://alii.pub/606j2h