How to make a bearing puller from blind holes from a bolt

Without a special puller, removing a bearing from a blind hole without damaging it and the seat itself is very difficult. If such a tool is not available, it can be made from available materials lying around in any garage. We offer a simple puller design that is easy to replicate.

You need to select a bolt with a diameter slightly smaller than the inner race of the bearing and cut it in half lengthwise. If it is rusty, then be sure to remove the threads first.

The sawn bolt is clamped in a lathe or drill.

You need to grind off its head, and instead make a small mushroom hook that can pry the bearing from below.

An insert between the bolt halves is cut from sheet steel. Its thickness should be enough to open it, and the fungus would cling to the bearing from below.

A ring larger than the outer race of the bearing is cut out of the pipe. It will rest against the body into which it is pressed. You also need to select a washer for the ring and weld it into it for convenience.

To use the tool, you need to insert the bolt into the bearing, put a ring with a washer on top, and tighten the nut.

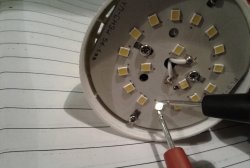

Then a spacer from the strip is inserted into the slot between its halves. Now if you hold the bolt with a screwdriver and tighten the nut, the tool will push out the bearing.

If the bearing sits tightly and you don’t have enough strength to hold the screwdriver, you can make a groove for a wrench at the end of the bolt.

It’s even better to weld another nut onto it, but so as not to block the gap for installing the spacer.

To prevent the fungus of the instrument from being torn off after a couple of uses, it will not hurt to harden it in oil.

Materials:

- bolt;

- screw;

- Sheet steel.

Puller manufacturing process

You need to select a bolt with a diameter slightly smaller than the inner race of the bearing and cut it in half lengthwise. If it is rusty, then be sure to remove the threads first.

The sawn bolt is clamped in a lathe or drill.

You need to grind off its head, and instead make a small mushroom hook that can pry the bearing from below.

An insert between the bolt halves is cut from sheet steel. Its thickness should be enough to open it, and the fungus would cling to the bearing from below.

A ring larger than the outer race of the bearing is cut out of the pipe. It will rest against the body into which it is pressed. You also need to select a washer for the ring and weld it into it for convenience.

To use the tool, you need to insert the bolt into the bearing, put a ring with a washer on top, and tighten the nut.

Then a spacer from the strip is inserted into the slot between its halves. Now if you hold the bolt with a screwdriver and tighten the nut, the tool will push out the bearing.

If the bearing sits tightly and you don’t have enough strength to hold the screwdriver, you can make a groove for a wrench at the end of the bolt.

It’s even better to weld another nut onto it, but so as not to block the gap for installing the spacer.

To prevent the fungus of the instrument from being torn off after a couple of uses, it will not hurt to harden it in oil.

Watch the video

Similar master classes

Particularly interesting

Comments (2)