You are unlikely to see a more functional grinder machine

For a small workshop, a factory belt sander is too bulky. Instead, it is better to get a homemade multifunctional attachment for an angle grinder, with which you can perform the same types of work.

A clamp is made from an aluminum plate to secure the grinder in place of the protective casing. A hole is drilled in the workpiece with a core drill, then the part is cut through with a tightening bolt. It is necessary to make its length with a margin for attaching the tension roller. .

In this part, its thickness will need to be cut in half.

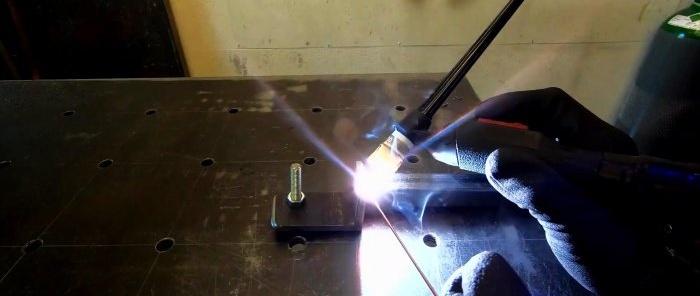

From a 100 mm pipe and a plate you need to weld a drive roller for the sanding belt. It is installed on an angle grinder instead of a cutting disc.

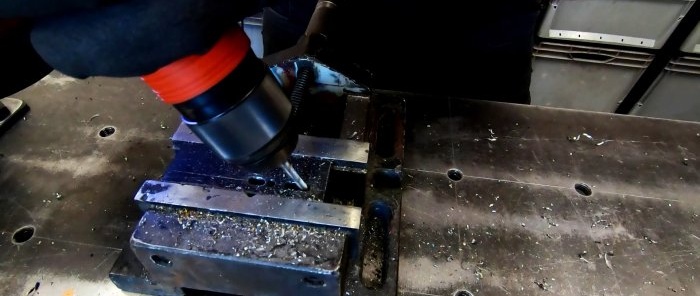

The roller must be sharpened to remove runout.

A guide with eyes is welded from a profile pipe.

It is screwed to the free part of the clamp on the angle grinder.

You will need to support the guide with a wing bolt in order to subsequently change the angle of attack of the roller to adjust the belt.

A retractable part with a guide is made from a thin profile pipe. A corner bracket with a tension roller for the tape is welded to its end. It will fit into the guide and press the compression spring inside.

The structure is assembled, and sanding belts of the required diameters are tried on it. To ensure tension, you will need to install a locking box that rests on the protrusion on the guide.

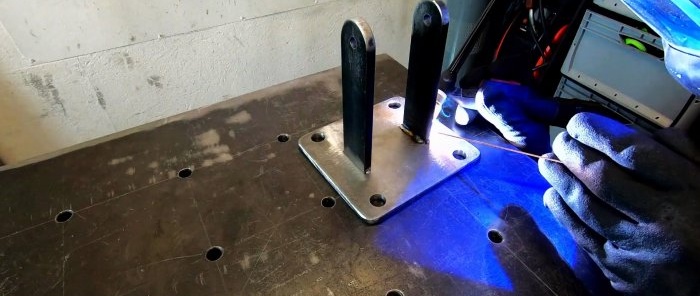

The base of the machine is welded from a steel plate with high eyes for installing an angle grinder using the standard holes for the handle. A crossbar is welded between the eyes for rigidity.

The work table is screwed to the driven roller bracket.

A hopper for collecting sawdust is attached to the bottom.

A thrust pad made of thin sheet steel is attached to the same bracket, which will limit the pulling of the belt during grinding. It must be mobile. To do this, it needs to be spring-loaded.

To sharpen knives strictly in one plane, you can make a special attachment for the machine. It is a horizontally located steel rod on a bracket, screwed to the work table near the driven roller. Under it you will need to make a knife clamp from two strips.

During assembly, the angle grinder is installed on the sole, then the remaining parts are attached to it. Before starting, the belt is tensioned; its position on the rollers can be adjusted with a wing bolt. If desired, it is possible to tighten the drive roller not with a nut, but with a Velcro support plate in order to obtain another grinding surface.

The design of the machine allows it to be rotated in two planes. You can install 2 work tables on it. One from the end, the second from the side between the rollers.

The machine can also be freed from the base and attachment to be used as an electric file. This is useful for stripping large workpieces.

When using a clamp and a guide rod, they will be convenient for sharpening knives with long blades.

Basic materials:

- aluminum plate 15-20 mm;

- pipe 100 mm;

- plate 4-5 mm;

- profile pipes 25x25 mm and 20x20 mm;

- sanding belt;

- compression springs – 2 pcs.;

- sheet steel 2 mm;

- rod 8-10 mm;

- tension roller with bearing.

Nozzle manufacturing process

A clamp is made from an aluminum plate to secure the grinder in place of the protective casing. A hole is drilled in the workpiece with a core drill, then the part is cut through with a tightening bolt. It is necessary to make its length with a margin for attaching the tension roller. .

In this part, its thickness will need to be cut in half.

From a 100 mm pipe and a plate you need to weld a drive roller for the sanding belt. It is installed on an angle grinder instead of a cutting disc.

The roller must be sharpened to remove runout.

A guide with eyes is welded from a profile pipe.

It is screwed to the free part of the clamp on the angle grinder.

You will need to support the guide with a wing bolt in order to subsequently change the angle of attack of the roller to adjust the belt.

A retractable part with a guide is made from a thin profile pipe. A corner bracket with a tension roller for the tape is welded to its end. It will fit into the guide and press the compression spring inside.

The structure is assembled, and sanding belts of the required diameters are tried on it. To ensure tension, you will need to install a locking box that rests on the protrusion on the guide.

The base of the machine is welded from a steel plate with high eyes for installing an angle grinder using the standard holes for the handle. A crossbar is welded between the eyes for rigidity.

The work table is screwed to the driven roller bracket.

A hopper for collecting sawdust is attached to the bottom.

A thrust pad made of thin sheet steel is attached to the same bracket, which will limit the pulling of the belt during grinding. It must be mobile. To do this, it needs to be spring-loaded.

To sharpen knives strictly in one plane, you can make a special attachment for the machine. It is a horizontally located steel rod on a bracket, screwed to the work table near the driven roller. Under it you will need to make a knife clamp from two strips.

During assembly, the angle grinder is installed on the sole, then the remaining parts are attached to it. Before starting, the belt is tensioned; its position on the rollers can be adjusted with a wing bolt. If desired, it is possible to tighten the drive roller not with a nut, but with a Velcro support plate in order to obtain another grinding surface.

The design of the machine allows it to be rotated in two planes. You can install 2 work tables on it. One from the end, the second from the side between the rollers.

The machine can also be freed from the base and attachment to be used as an electric file. This is useful for stripping large workpieces.

When using a clamp and a guide rod, they will be convenient for sharpening knives with long blades.

Watch the video

Similar master classes

The simplest grinder made from a grinder, a bicycle hub and a roller

How to make a grinder attachment for an angle grinder

How to make a belt grinder without welding on the base

Do-it-yourself miter saw based on a grinder with a broach

How to make a cross-cutting machine from an old bicycle and an angle grinder

This grinder machine cleans rusty pipes in no time

Particularly interesting

Comments (0)