Making liquid plastic for anti-corrosion coatings with your own hands

While repairing my car, I was faced with the need to protect body parts from rust, while the materials available to me were either expensive or not effective enough. After several days of searching, the question arose, what is stopping me from preparing the composition for the anti-corrosion coating with my own hands. By and large, such materials are liquid plastics, in other words, they are polymers dissolved in organic solvents.

The matter is basically simple. At the first stage, it is necessary to select a plastic and a solvent for it, at the second, grind the raw materials and add a reagent. What happened as a result of the implementation of this idea: read in the review.

Tools you will need: pliers and a large file (rasp).

Using your hands or using pliers, crumble the black plastic; the smaller the fragments, the better. Ideally, it should be turned into powder (flakes) with a rasp.

We carry out a similar operation for plexiglass, putting the pieces into a container for analysis.

Fill the crushed plexiglass with “646” solvents, and the plastic with xylene.

We pour enough liquid so that it completely covers the polymer raw material with a small margin. Plexiglas makes a good varnish; you can add a little xylene to slow down its polymerization.

Shake the containers with our compositions thoroughly and leave them in a warm room for a couple of days. The container must be tightly closed to prevent the possibility of solvent evaporation.

After this period, we open the containers and observe the result. Plastic and plexiglass completely dissolved and became suitable for anti-corrosion treatment of metal parts.

We check the properties of the resulting composition: we lower a metal rod into it and see that the liquid plastic has high adhesion to its surface.

We apply the anti-corrosion compound with a brush to parts of the car body that need protection from rust. It is better to make a two- or three-layer coating with intermediate maintenance of each layer until completely dry.

During work, it is necessary to observe safety precautions with active chemical liquids. The solvents used have a pungent odor and the room in which you conduct the experiments must have good ventilation.When pouring it into a container, you need to be very careful to avoid contact with the skin and mucous membranes.

The matter is basically simple. At the first stage, it is necessary to select a plastic and a solvent for it, at the second, grind the raw materials and add a reagent. What happened as a result of the implementation of this idea: read in the review.

Materials and tools used

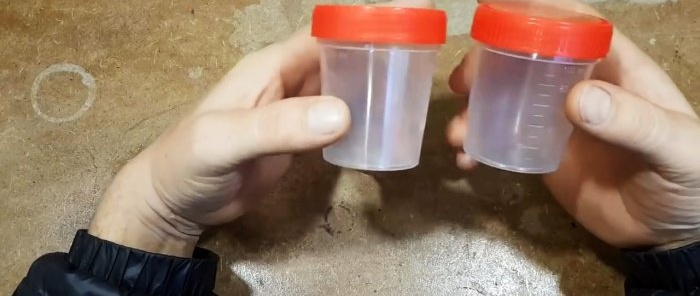

- Two test jars with tight-fitting lids.

- For large volumes, you can use a bottle (PET) of vinegar or solvent as a container.

- Pieces of various types of plastic: in our case, black is a fragment of the charger case, transparent is plexiglass, gray is from some kind of electronic device.

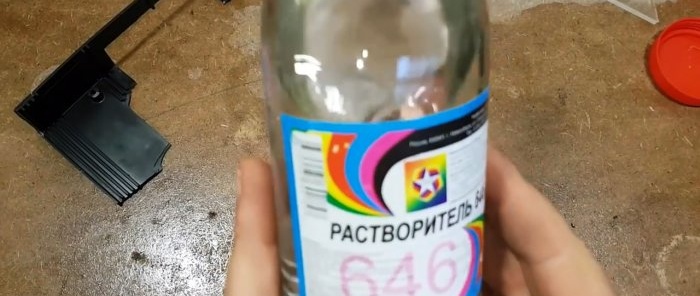

- Three types of solvents: “646th”, acetone and xylene (for car enamels).

Tools you will need: pliers and a large file (rasp).

The process of preparing liquid polymer

Using your hands or using pliers, crumble the black plastic; the smaller the fragments, the better. Ideally, it should be turned into powder (flakes) with a rasp.

We carry out a similar operation for plexiglass, putting the pieces into a container for analysis.

Fill the crushed plexiglass with “646” solvents, and the plastic with xylene.

We pour enough liquid so that it completely covers the polymer raw material with a small margin. Plexiglas makes a good varnish; you can add a little xylene to slow down its polymerization.

Shake the containers with our compositions thoroughly and leave them in a warm room for a couple of days. The container must be tightly closed to prevent the possibility of solvent evaporation.

After this period, we open the containers and observe the result. Plastic and plexiglass completely dissolved and became suitable for anti-corrosion treatment of metal parts.

We check the properties of the resulting composition: we lower a metal rod into it and see that the liquid plastic has high adhesion to its surface.

We apply the anti-corrosion compound with a brush to parts of the car body that need protection from rust. It is better to make a two- or three-layer coating with intermediate maintenance of each layer until completely dry.

During work, it is necessary to observe safety precautions with active chemical liquids. The solvents used have a pungent odor and the room in which you conduct the experiments must have good ventilation.When pouring it into a container, you need to be very careful to avoid contact with the skin and mucous membranes.

Watch the video

Similar master classes

Particularly interesting

Comments (25)