How to quickly cast a cable boss without an injection mold

Sometimes such a nuisance happens as the cable breaks and the factory boss at the end flies off. To make a new one, you need an injection mold that will form the outer contours of the metal. Of course, you can do it yourself, but it will take a lot of time and effort. And it’s not a fact that you will have all the parts for it and the manufacturing machines.

I will demonstrate a simple way, a life hack, on how to cast a new boss in literally 5 minutes. And we’ll make a mold for filling from a piece of wood. Yes, yes, it’s made of wood. Almost everyone, even the most shabby craftsman, has an ordinary board and drills.

Will need

- Flux, preferably in paste.

- Tubular solder.

- Gas burner with cylinder.

- Wooden block (piece of board).

We cast the cable boss into a wooden block

It is necessary to securely secure the block, say in a vice. Next, drill a blind hole with a diameter of approximately 8 mm - this will be the future diameter of the boss.

Then a hole is drilled on the side along the thickness of the cable, which passes through the large one.

Let's start casting

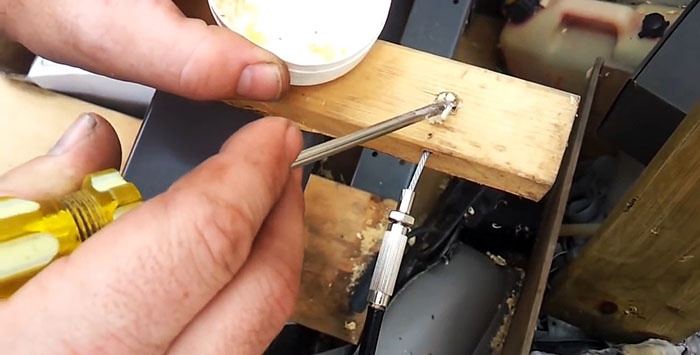

Insert the cable into the hole from the side until it stops.

Add plenty of flux.It will not only perform the function of adhesion of solder to metal, but will also protect the walls of the casting mold from destruction.

Turn on the burner and heat up the flux. The wood begins to char immediately - this is normal.

After 5 seconds, introduce tubular solder.

Add it until it comes in and there is no excess on top.

After the recess is filled, we continue to heat it so that the metal spreads evenly and no voids form inside.

We are waiting for it to cool down. You can water it with water.

Using a knife, we cut through the charred wood to free the cable.

Here is the boss after casting. Rough, but the process is not over yet.

We modify it with a file according to the dimensions of the factory boss. The metal is soft, everything is done very quickly.

After processing it is indistinguishable from the factory one.

We install it in the brake lever and start using it.

Watch the video

Similar master classes

Particularly interesting

Comments (2)