Homemade flange for electric motor shaft

If it is necessary to attach a grindstone, brush, pulley, blades or other equipment to the motor shaft, a flange is required, which can be difficult to select. If you have the desire and free time, you can make such an adapter yourself from inexpensive materials. To make a flange, you will need a minimum of tools: a hacksaw or grinder, a drill and a tap with a holder.

Required materials:

First you need to decide on the desired length of the flange in order to cut the stud correctly. Subtract half of the extended nut from the required length. For example, if you need a 100 mm flange, and the length of the extended nut is 48 mm, then the stud is cut 24 mm shorter, that is, you will need a 76 mm piece.

The stud cut must be screwed into the extended nut half its length. To ensure a reliable connection, the screw-in thread is pre-lubricated with two-component metal adhesive.When screwing in, excess glue will be squeezed out, which must be wiped off immediately. After this, the workpiece is left overnight so that the composition hardens. If you have welding equipment, then fastening the parts tightly together will not be difficult and will come out faster.

On the second half of the elongated nut, use a 5 mm drill to make 2 holes on one side. The distance between them should allow you to then screw in 2 bolts so that their heads do not touch. Next, the holes are threaded with an M6 tap. If a flange of a different diameter is made, then bolts for it are selected that are comparable in size.

The resulting holes on the extended nut are necessary to tighten the flange on the motor shaft. To do this, screw 2 M6 bolts into them. To prevent the design from being cumbersome, it is advisable to shorten them first by trying on the workpiece on the shaft of a motor or generator.

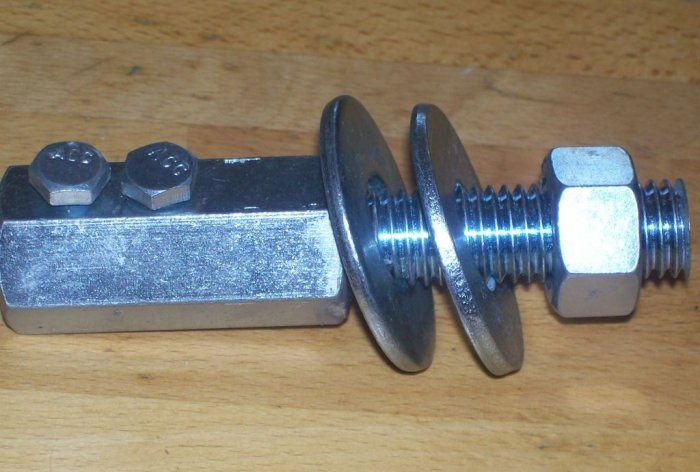

The nozzle is almost ready, all that remains is to thread 2 washers and a clamping nut onto the stud.

The equipment that will need to be installed on the motor shaft will be clamped between the washers. The flange itself is quick-detachable, so it can be installed on other electric motors if necessary.

The adapter flange is assembled quickly, but a technological pause is required for the glue to harden. If you use electric welding to weld the extended nut to the stud, it will take less than an hour. At the same time, using such an attachment is very simple, since by clamping the equipment in it, you can fix the second wrench to rest on the extended nut.

Original article in English

Will need

Required materials:

- M16 stud (or other diameter corresponding to the motor shaft);

- nut M16;

- 2 washers M16;

- extended nut M16;

- 2 M6 bolts;

- two-component adhesive for metal (cold welding).

Flange assembly

First you need to decide on the desired length of the flange in order to cut the stud correctly. Subtract half of the extended nut from the required length. For example, if you need a 100 mm flange, and the length of the extended nut is 48 mm, then the stud is cut 24 mm shorter, that is, you will need a 76 mm piece.

The stud cut must be screwed into the extended nut half its length. To ensure a reliable connection, the screw-in thread is pre-lubricated with two-component metal adhesive.When screwing in, excess glue will be squeezed out, which must be wiped off immediately. After this, the workpiece is left overnight so that the composition hardens. If you have welding equipment, then fastening the parts tightly together will not be difficult and will come out faster.

On the second half of the elongated nut, use a 5 mm drill to make 2 holes on one side. The distance between them should allow you to then screw in 2 bolts so that their heads do not touch. Next, the holes are threaded with an M6 tap. If a flange of a different diameter is made, then bolts for it are selected that are comparable in size.

The resulting holes on the extended nut are necessary to tighten the flange on the motor shaft. To do this, screw 2 M6 bolts into them. To prevent the design from being cumbersome, it is advisable to shorten them first by trying on the workpiece on the shaft of a motor or generator.

The nozzle is almost ready, all that remains is to thread 2 washers and a clamping nut onto the stud.

The equipment that will need to be installed on the motor shaft will be clamped between the washers. The flange itself is quick-detachable, so it can be installed on other electric motors if necessary.

The adapter flange is assembled quickly, but a technological pause is required for the glue to harden. If you use electric welding to weld the extended nut to the stud, it will take less than an hour. At the same time, using such an attachment is very simple, since by clamping the equipment in it, you can fix the second wrench to rest on the extended nut.

Original article in English

Similar master classes

Particularly interesting

Comments (5)