How to easily make a twisted harness for laying wires

During construction or renovation, it happens that we do not always know how to correctly calculate the quantity and consumption of building materials. It may happen that upon completion of the repair there may be a slight shortage of one or another material. Some citizens are in such a hurry to complete the repairs as quickly as possible that they carry them on until late at night, not paying attention to the angry cries of their neighbors. However, willy-nilly, you will have to interrupt this exciting activity if at least one of the consumables runs out. And it’s too late to run to the store. But there is always a way out. In this master class we will talk about the mounting spiral.

You can also use these twisted bundles for laying computer wires under the computer table, to avoid their tangling.

A mounting spiral or twisted harness is not a necessary thing, but with it things will go much faster if you are laying the wiring in a slotted groove in the wall, or in an electrical box. When laying several wires in one groove, to avoid their scattering, a twisted harness comes in handy. And if it suddenly runs out, a hose of suitable diameter will help us.If such, of course, is available. I think during any construction, a hose (or a piece of hose) will always be found. From a small piece, for example, a meter long, you can easily make a spiral that will stretch up to five to seven meters! You can also save money at the beginning of the repair, do not buy a mounting spiral, but buy any cheap PVC hose, which you will need five times less in length, and turn it into a spiral using a couple of methods, which I will demonstrate below. The first method is for a larger hose, the second method is for a smaller hose.

For method 1 you will need

- A piece of plastic (or metal-plastic) pipe, approximately 10 cm long, into which the hose you have chosen will fit effortlessly.

- Blade from a stationery knife (or from a technical scalpel).

- Secondary glue and soda.

- Nice, thick knife.

- Pliers.

So, we decided on the diameter of the hose. Now let’s select the required pipe diameter.

The pipe should not be too wide, but not too narrow, so that the hose can be threaded freely into it without dangling there. Next, we make an oblique cut on the pipe with a knife, as shown in the photo:

Use pliers to break off part of the blade from the stationery knife.

We insert the tip into the cut on the pipe so that the tip of the blade protrudes inside the pipe by about four to five millimeters.

Fix the blade in the cut with instant glue and sprinkle with soda.

We wait a minute or two for the glue and soda to completely harden. We insert the hose into the tube with the blade, and turn the hose towards the tip of the blade. A ready-made spiral will come out of the other hole in the pipe.

If your hose is long, then the tube can be clamped in a vice for greater convenience, and if it is short, then you can hold it in your hand.And one more thing, the more oblique, relative to the length of the plastic tube, we make the cut for the blade, the larger the spiral pitch will be. You can make several different cuts at once, at different angles, and then simply move the blade to one cut or another, depending on the spiral pitch you need.

For method 2 you will need

- The tube is metal, with a caliber slightly smaller than the inner diameter of the hose.

- File or file for metal.

- A powerful lighter or soldering iron with tin and flux.

- A piece from a stationery knife blade.

- A screwdriver that will fit into the tube.

Preparing this tool for making a spiral from a thin hose will not take much longer than in the first method. However, this tool will last longer. Here the principle of operation is the same as in the first method, only the spiral will no longer be cut from inside the tube, but from the outside. So, using a thin file or metal file, we make the same cut on the tube as in the first method.

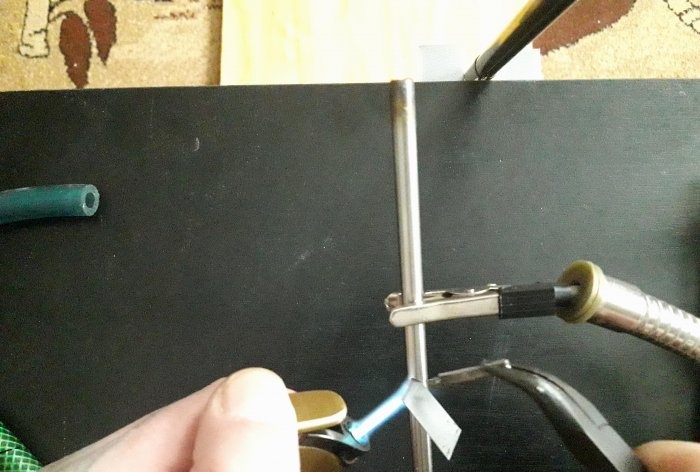

We coat the cut and blade with flux, insert the blade into the cut, heat it with a lighter, and apply solder.

It's a matter of one minute! Next, again for convenience, we put the tube with a soldered blade on a suitable screwdriver (or other handle), put our hose on the tube until it rests on the blade and, rotating the hose towards the tip of the blade, we cut the spiral. Many people will think that they can just stick the blade into, say, a pencil, secure it with glue and cut to their heart’s content, but I’ll say right away that you can’t cut much with such a tool. And this same tool can be used constantly when the need arises, if you carefully tidy it up after finishing work. In this simple and fairly quick way (or rather ways), you can complete part of the repair without waiting for the store to open.

Usage: