Repair of torn hinges

We have a rare thing in our family - a stereo system in a wooden case with a glass facade. Unfortunately, during transportation the top cover was broken off the awnings. I decided to restore it, at the same time making a small instruction, because the technology I used is suitable for repairing other hinges of a similar design.

Required tools and materials

Tools you will need:

- Two clamps or other devices for spacers.

- Square or square.

- Insulating tape.

- Chisel and hammer.

- Circular Saw.

- Rasp and sandpaper.

- Electric drill.

Materials required for repair:

- A wooden block, preferably hardwood.

- Wood glue or PVA.

- 4 wooden pins.

Do-it-yourself repair of torn hinges

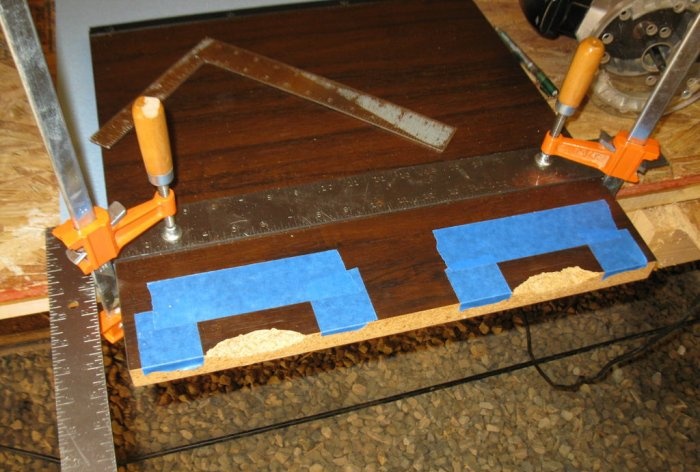

Preparation. Using a square and a pen, I outlined the area around the damage to the lid that would then need to be selected. For greater clarity, I covered the drawn lines with blue tape.

Then I cut grooves with a circular saw (not to the full depth of the lid), and carefully hollowed out the wood with a chisel. I had to tinker with the corners of the recess, since it was not possible to cut through these places with a disk.Then I trimmed the selected grooves with a rasp and sanded them with sandpaper. It turned out smooth and neat.

Preparation and installation of the mortgage. The next step is to prepare a wooden embed (preferably made of larch, as it is harder) for the cut area. The block must be carefully adjusted in size and fit tightly enough. I coated everything with glue and pressed it down with clamps so that it would stick together under pressure.

Then I drilled through holes at the ends of the mortgages, and also drilled the cover 5 cm in order to use additional fixation using wooden pins.

They were also coated with glue and hammered into the prepared holes. Leave the press overnight to ensure it seals well.

Completion of work and assembly. The next day, I removed the clamps and clamps that were used to additionally secure the mortgages, cut the wooden pins and sanded the end. Then I coated the fresh wood with two coats of mahogany stain. It turned out almost the same color as the original coating.

The final stage is screwing the hinge to the lid and adjusting it with screws so that the lid moves easily and fits tightly into place when closed.

That's all, I hope this repair method will be useful to someone in a similar situation.

Original article in English

Similar master classes

Particularly interesting

Comments (9)