Battery desulfator from junk

Hi all! It is quite possible to make a simple desulfator from old and unnecessary things in about 15 minutes, if, of course, you know what to make and from what. Any normal radio amateur has a lot of all kinds of electronic junk. And if you scratch the bottom of the barrel, you can find everything you need. In principle, everything is accessible and interchangeable.

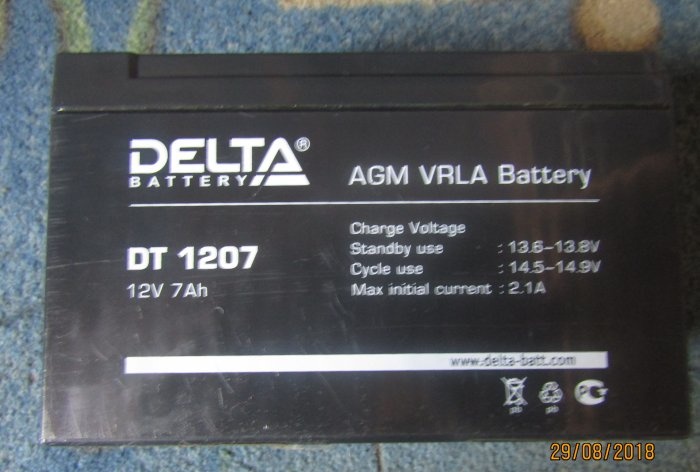

So, lead batteries are susceptible to sulfation. This is a process in which the battery plates are coated with sulfate. This phenomenon causes the battery to deteriorate in terms of capacity and current.

In order to get rid of sulfate deposits, I will expose the battery to high voltage at high frequency.

I will take the high voltage from the power supply board for the mercury lamp of the document scanner. I won’t show you how to find it in the scanner and connect it, since this is individual for each scanner.

I connect a copper plate covered with an insulator at the edges to the tip of one of the high-voltage wires. And we screw the second high-voltage wire to the battery terminal.

After this, we supply power to the board with 12 Volts. Attention! Dangerous voltage!

Now you need to clamp the plate on the second terminal of the battery so that there is no direct contact. And the current passed through the shortest possible spark arc.

To get the best result it is necessary. Apply high voltage to the battery for 30 minutes to 3 hours. Then turn off this design and put the battery on charge. Then unload and repeat all over again.

Repeat until the battery capacity increases.

You can also hit with a shaker. This technique is also applicable to ni-CD batteries.

So, lead batteries are susceptible to sulfation. This is a process in which the battery plates are coated with sulfate. This phenomenon causes the battery to deteriorate in terms of capacity and current.

In order to get rid of sulfate deposits, I will expose the battery to high voltage at high frequency.

I will take the high voltage from the power supply board for the mercury lamp of the document scanner. I won’t show you how to find it in the scanner and connect it, since this is individual for each scanner.

I connect a copper plate covered with an insulator at the edges to the tip of one of the high-voltage wires. And we screw the second high-voltage wire to the battery terminal.

Let's move on to battery recovery

After this, we supply power to the board with 12 Volts. Attention! Dangerous voltage!

Now you need to clamp the plate on the second terminal of the battery so that there is no direct contact. And the current passed through the shortest possible spark arc.

To get the best result it is necessary. Apply high voltage to the battery for 30 minutes to 3 hours. Then turn off this design and put the battery on charge. Then unload and repeat all over again.

Repeat until the battery capacity increases.

You can also hit with a shaker. This technique is also applicable to ni-CD batteries.

Watch the video

Similar master classes

Particularly interesting

Cable antenna for digital TV in 5 minutes

A selection of simple and effective schemes.

Three-phase voltage from single-phase in 5 minutes

Starting a three-phase motor from a single-phase network without a capacitor

Eternal flashlight without batteries

How to make an inexpensive but very powerful LED lamp

Comments (9)