Compact folding chair (table) made of square profile

This folding chair is convenient in the home, in the country or in the garden. To make it you will need the simplest materials. It is better, of course, to work with a mechanized tool, but you can get by with a hand tool. This work can be done by any adult with skills in handling metal and wood.

By changing the dimensions, you can easily make an excellent table instead of a chair.

Will need

Materials:

- profile square pipe;

- bolts and nuts;

- spray paint;

- 2 wooden boards 40 cm long;

- self-tapping screws or self-tapping screws.

Tools: carpenter's marking square, marker, center punch, drilling machine, grinder, hammer, welding, circular saw, jointer, milling machine, grinder and drill.

The process of making a folding chair from a profile metal pipe and wood

We cut the profile square pipe into 4 sections of 45 cm, 2 – 35 cm and 4 – 30 cm. On four sections of 45 cm, measure 30 cm from the end and draw transverse lines.At the other end of these segments and on four 30 cm segments, we set aside 1 cm from the edge and also draw transverse lines along the surfaces of all segments.

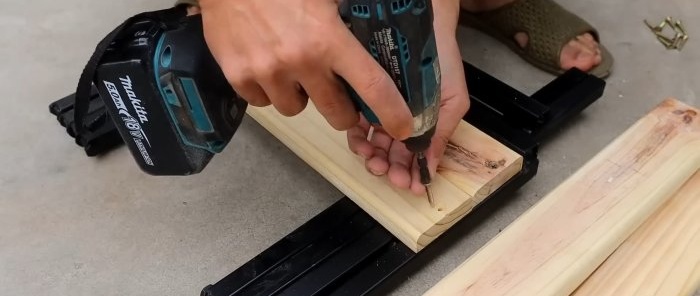

We make cores in the center of all lines using an automatic center punch and drill through holes on a drilling machine.

The ends of all segments with holes along the edges are rounded with a grinder. We connect the 45 and 30 cm sections into 2 pairs using bolts, first passed through the holes of the 45 cm sections.

We cut off the protruding parts of the bolts, leaving only a small part, which we flare with a hammer, but at the same time leaving the connection movable. We also connect the remaining 2 pairs with bolts, but place nuts between the segments.

We also connect pairs of segments separated by nuts with a pair without nuts using bolts and also flare the ends of the bolts, but without disturbing the mobility of the joints relative to each other.

We measure 10 cm from the free ends of the long segments and draw transverse lines. We lay a 35 cm long section on the line in the transverse direction and weld it to the outer 45 cm long sections, ensuring right angles at the joints using magnetic corners.

In the same way, we place a section of a square pipe on the free ends of the 30 cm long sections in the transverse direction and weld them, ensuring right angles at the welding points.

We turn the structure 180 degrees and weld the transverse section to the internal long sections along the edges. We control the outer transverse dimension, which should be exactly 40 cm. On the same side, we use a transverse section of a square pipe to connect short outer sections by welding.

We paint the fully assembled metal frame of the folding chair with spray paint and while it dries, we will work on the wood in the form of two thick boards 40 cm long.

We pass them through a jointer on all four sides, flatten them into bars with a circular saw, process them with a grinding machine and round the longitudinal edges on both sides on a milling machine.

We screw the wooden seat elements to the metal frame with self-tapping screws, having previously drilled holes in them along the edges. The chair unfolds easily, has sufficient strength and rigidity, is easy to assemble, and at the same time takes up little space.