How to make rollers for grinder

In the design of this grinding machine, an important place is given to rollers or rollers. The drive roller sets the abrasive belt in motion, the tension roller picks up the slack, the driven rollers hold and impart uniform tension to the abrasive belt.

The rollers should be light, durable, and the surface should be smooth. You can make them yourself and you don’t need to be a professional.

To make rollers you will need the following materials and products:

We will carry out the work using the following tools and devices: a circular, circular and jigsaw, a drilling and lathe, a file and sandpaper, a hammer and wrenches, a device for centering squares, etc.

Using a circular saw, we cut the multilayer plywood into six rectangular fragments, the long side of which is exactly twice as large as the shorter side.

We mark with a pencil using a device for centering square blanks the middle of the halves of rectangular fragments and mark the found centers with a center punch.

We make blind holes for ball bearings on a drilling machine using a Forstner drill.

Then, using a core drill of a larger diameter, we obtain two round disks from each rectangular fragment.

Using a hammer and a piece of multi-layer plywood, we press sealed ball bearings flush into the blind holes.

We make through holes in all disks in the center with a drill with a diameter corresponding to the size of the inner ring of the bearings.

We thread three round disks onto the bolt and washer using glue. We place a wide washer on top and tighten the block with wrenches and leave it until the glue hardens.

Next, unscrew the nut and remove the tightening bolt. Now we have at our disposal three monoblocks with bearings pressed into the outer disks.

Using a pendulum saw, we cut three pieces from a plastic pipe of the required diameter, equal in length to the height of monoblocks of three disks made of multi-layer plywood.

We grind the side surfaces of the monoblocks, securing them in the chuck of a drilling machine, first with a roughing file, then with sandpaper, to the inner diameter of the pieces of plastic pipe, controlling the turning with a caliper.

We press the turned monoblocks with bearings at the ends into pieces of plastic pipes, using the tool feed mechanism of the drilling machine as a press. If the process is difficult, lightly sand the side surface of the monoblock with sandpaper.

We remove the bolts and our tension and driven disks are almost ready.Once again we check the pressing of the bearings and, if necessary, seat them. We process the ends of the rollers on a grinder.

The rollers should be light, durable, and the surface should be smooth. You can make them yourself and you don’t need to be a professional.

Required

To make rollers you will need the following materials and products:

- multilayer plywood;

- sealed ball bearings;

- tube of wood glue;

- bolts, washers and nuts;

- plastic pipes.

We will carry out the work using the following tools and devices: a circular, circular and jigsaw, a drilling and lathe, a file and sandpaper, a hammer and wrenches, a device for centering squares, etc.

The process of making grinder rollers

Using a circular saw, we cut the multilayer plywood into six rectangular fragments, the long side of which is exactly twice as large as the shorter side.

We mark with a pencil using a device for centering square blanks the middle of the halves of rectangular fragments and mark the found centers with a center punch.

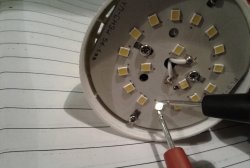

We make blind holes for ball bearings on a drilling machine using a Forstner drill.

Then, using a core drill of a larger diameter, we obtain two round disks from each rectangular fragment.

Using a hammer and a piece of multi-layer plywood, we press sealed ball bearings flush into the blind holes.

We make through holes in all disks in the center with a drill with a diameter corresponding to the size of the inner ring of the bearings.

We thread three round disks onto the bolt and washer using glue. We place a wide washer on top and tighten the block with wrenches and leave it until the glue hardens.

Next, unscrew the nut and remove the tightening bolt. Now we have at our disposal three monoblocks with bearings pressed into the outer disks.

Using a pendulum saw, we cut three pieces from a plastic pipe of the required diameter, equal in length to the height of monoblocks of three disks made of multi-layer plywood.

We grind the side surfaces of the monoblocks, securing them in the chuck of a drilling machine, first with a roughing file, then with sandpaper, to the inner diameter of the pieces of plastic pipe, controlling the turning with a caliper.

We press the turned monoblocks with bearings at the ends into pieces of plastic pipes, using the tool feed mechanism of the drilling machine as a press. If the process is difficult, lightly sand the side surface of the monoblock with sandpaper.

We remove the bolts and our tension and driven disks are almost ready.Once again we check the pressing of the bearings and, if necessary, seat them. We process the ends of the rollers on a grinder.

Watch the video

Similar master classes

Particularly interesting

Comments (2)